Mfano ya kazi za vipengele vya kiutamaduni aktivi, katika muda wa zamani zilipita kabla ya usimamizi wa elektroniki. Watu walikuwa wanajitolea bila kutumia rahisi za sasa tunayotumia sasa. Hata hivyo, vipengele vya elektroniki vinavyojulikana katika dunia yetu ya sasa. mchanganyiko wa mitandao inapatikana kutumika kusimamia upima wa upepo elektroni mwandao smartphone zetu, kompyuta za kifupi na mbalimbali ya sayansi nyumbani kama mikrovi asauza au baridi. Vipengele vyovyote vya elektroniki, si kama hayo ya kupasiva, hawapati nguvu ili kazi yao iwe sawa na kipofu. Zinapaswa kuwa na nguvu ya batari au kukubaliana na ndege. Hii inaweza kufanya kwa kuchoma vitabu vya kazi kama vile kuboresha alama na kutumia uzito wa mchanganyiko wa idadi ya mitaa ili kuhakikisha kazi za mashine yetu.

Active electronic components inahusisha jukumu muhimu katika jamii la leo. Uwezo wa kutungamiana unategemea kwa teknolojia ya usimamizi. Bila vipengele vya barua na digital kwa upanaji, vitu kama simu na internet ambazo ni muhimu kwa mchakato yetu yote hawatukuwepo. Wao ndio wanaojisimamia mengi ya mwenendo tunayopendeza, kama kuangalia mchezo yetu favoriti na filamu, kusikia muziki favoriti yetu, na kucheza video games.

Vifaa vya afya kama stethoscopes, magari, na kadhalika wanapotumia ili kupunguza habari muhimu kama mchanganyiko wa moyo kwa dakika. Bita ina hesabu wa kiwango cha oxygen katika damu yetu. Mambo haya ni muhimu kwa kuboresha kuwa wapenzi pia pata usambazaji sahihi wakijaribu zaidi. duka la mipangilio ya digital iliyotengenezwa na mailin ina kifani kikubwa katika sehemu ya afya za maisha yetu. Haya ni mambo yanayowafanya kazi ya kuhakikisha ugonjwa au si rahisi.

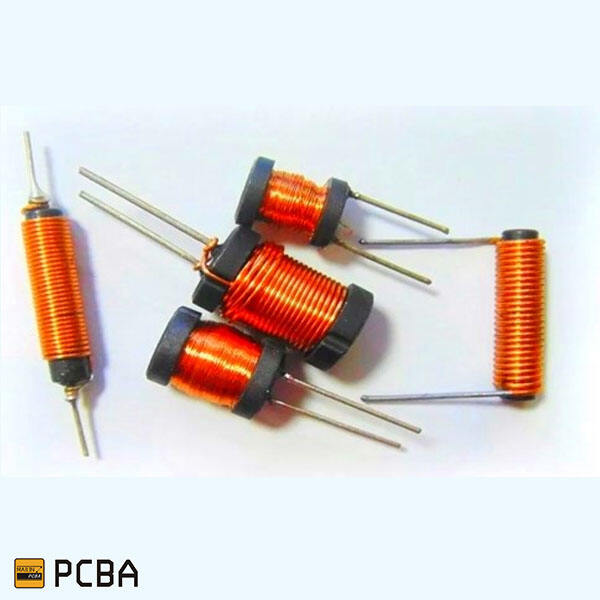

Muhimu wameleta jinsi iliyoyogelea mchanganyiko elektroniki minginevyo ili kuboresha mengine ya juhudi elektroniki ambayo ni mbalimbali. Kwa mfano, transistors zinapatikana kwa ajili ya kuboresha au kushuka alama za elektroniki. duka la vipangazo vya digitali inahitajika kwa kompyuta na mifumo mengine ili kazi zao zipate kuhifadhi vizuri. Wakati unapokuzunguka kuhakikisha uzalishaji wa nguvu ya AC hadi DC, inahitajika sehemu ambayo inaruhusu usio wa nguvu katika upande mmoja tu, na diodes ni aina moja yoyote hapa ndani ya kundi hili. Capacitors huendesha pamoja naye, inapewa njia rahisi ya kuhifadhi na kuchukua fedha ya kiroba kwa ujumbe mbalimbali wa uzalishaji wa nguvu au funguo la maneno. Hizi ni sehemu ambazo yanafanya kazi pamoja ili kuhakikisha malengo yote yamepita vizuri. Ni muhimu kuhakikisha kwamba sehemu za kielfiki aktibu bado ni sehemu muhimu katika mizizi ya teknolojia ya sasa. Muhimmijari na wachambaji wanaweza kabisa kutaka kufanya sehemu hizo kwa haraka, ndogo zaidi, na kuboresha zaidi. Vitabu vya kupendekeza hivi karibuni vilivyopatikana katika uzalishaji wa kitambaa. Smart watches na fitness trackers vinaweza kusimamia masharti ya active electronic components kwa kusaidia kuhakikisha afya yetu. Sehemu za kifedha chache zinaweza kuhakikisha wasioziweka kila siku, mshale wa moyo, na kukubaliana na mambo yanayotokea.

Wanajamii wengi wa mitaa yanayofanya kazi pia vinapatikana katika teknolojia ya usimamizi wa nguvu inayotenganuliwa. Kwa mfano, mahusiano haya ni muhimu katika kuboresha mwezi kuwapunguza upepo kupitia makani au ni muhimu katika kuhakikisha malengo ya vumbi na mito ya nguvu yanavyopendekezwa, hivyo inapokuja kuanza kutegemea uzalishaji wa nguvu wa kifumo na upatikanaji wa nguvu. matumizi ya kiuchumi ya kifundi kupitia mailin ni muhimu kwa teknolojia tunayotumia kila siku na ni muhimu kwa maisha yetu yoyote. Wao inasaidia katika funguo mbalimbali au sehemu za mfumo ili kazi iweke zinazofanya kazi vizuri, usiothezavyo kitu chochote ichukue mstari. Transistors ni muhimu kwa upimaji wa haraka katika kompyuta, wakati diodes ni muhimu kwa picha safi nyaraka juu ya TV. Mwishowe, capacitors inaweza kusimamia spika zinaweza kutengeneza sauti nzuri, inatupa kupendeza ndoto zetu na filamu favoriti zetu katika ubora ungfwa.

ni mteja wa kutosha katika kuleta suluhisho la usambazaji wa PCBA kwa haraka Active komponeti za mitaa ya kiuchumi muhimu na ufaamu. kwa ajili ya makazi yoyote tunavyotengeneza mchanganyiko wetu kwa uzalishaji na kuboresha utawala wa mbali, inapunguza miezi ya kupitia miaka 10, inapong'aa sana juu ya jukumu la sehemu. Pia, kwa upate wa haja mbaya, tumeleta huduma za kupitia kwa haraka kwa ajili ya mikopo ndogo pamoja na muda wa kurekebisha wa tu 72 saa. itakuwa na faida kwa kutetea vile vyovyote vichane vikae kwa kupita.

Muhatia 2009, kampuni ilijengwa. Hangzhou Hezhan Technology Co., Ltd ina eneo la 6,000 mita kavu, linapong'za chumbani la kifurushi la sasa la kisasa kwa ajili ya uwekezaji wa viongozi elektroniki. Kampuni inatafuta katika upatikanaji wa kifupi elektroniki na inaruhusu kwa ushirikiano wakiolewa wateja mahitaji yao kamili za PCBA. Kuhusu 150 wanajamii wanafanya kazi kwa kampuni, ambayo pia inamaanisha timu ya uzalishaji wenye kiraia 100 watu, kundi la utafiti na maombi la asili la kiraia 50, wasimamizi na timu ya mstari. Pia kuna kundi la OEM lisilo la mbali. Hezhan Technology, ambalo ina biashara ya mwaka juu ya 50 milioni yuan, imepunguza kuboresha kwa miaka ya Active electronic components. kiwango cha kuboresha cha asili kwa miaka mitatu ya karibuni ni zaidi ya 50%, ambayo inaonyesha kwamba ni katika fase ya kuboresha kwa haraka.

Tunajishughulikia makomponenti ya elektroniki ya Active na ushirikiano wa kubwa zaidi na wateja wetu kuhakikisha upatikanaji wa kifaa na huduma za PCBA One-stop. Utambuzi wa SMT ni ndogo sana na utafiti wa kiwango cha ubora wa upakaji, mpaka katika uwezo wa usambazaji wa DIP, na jaribio la PCBA linahitajika kama mchakato muhimu wa kuhakikisha kiwango cha upato na kupewa. Jaribio la FCT inapunguza na kutesteshwa ili kuunganisha viwango vya ujaribio uliovutia na wanachama, programu, na hatua. Kila mdundi unavyopendekeza kwa nguvu mahitaji ya kiwango cha bidhaa na hii ni juu zaidi duniani, kuhakikisha kuwa bidhaa inapatikana pamoja na uzito wa kipimo cha kutosha na uzito wa muda mrefu.

Tunaelewa vizuri ya uhai mbili wa jukumu la kila mstari wa Active elektroniki, kwa hiyo katika huduma za usafiri usio na wakati moja ambazo tunatoa PCBA tunapokubaliana sana na thamani muhimu ya "huduma ya mteja iliyopangwa". Tunatoa huduma za shauri la kifurushi la pepe la kipekee ambalo inathibitisha kuwa kila mteja anapewa suluhisho la kipengele cha mwisho. Timu yetu ya wanasayansi wanaweza kuweka mahali pa namba mbili za suluhisho, kutoka kwa fase ya kuanzisha kwa uchambuzi hadi kuthibitisha masharti. Wao wanajisimamia pamoja na mteja, wakiongoza mchanganyiko wa huduma kwa fleksi ya kupendekeza na kujibu mahitaji yoyote ya mradi, iwe rahisi au mchanganyiko, kwa kuboresha na nguvu ya teknolojia.