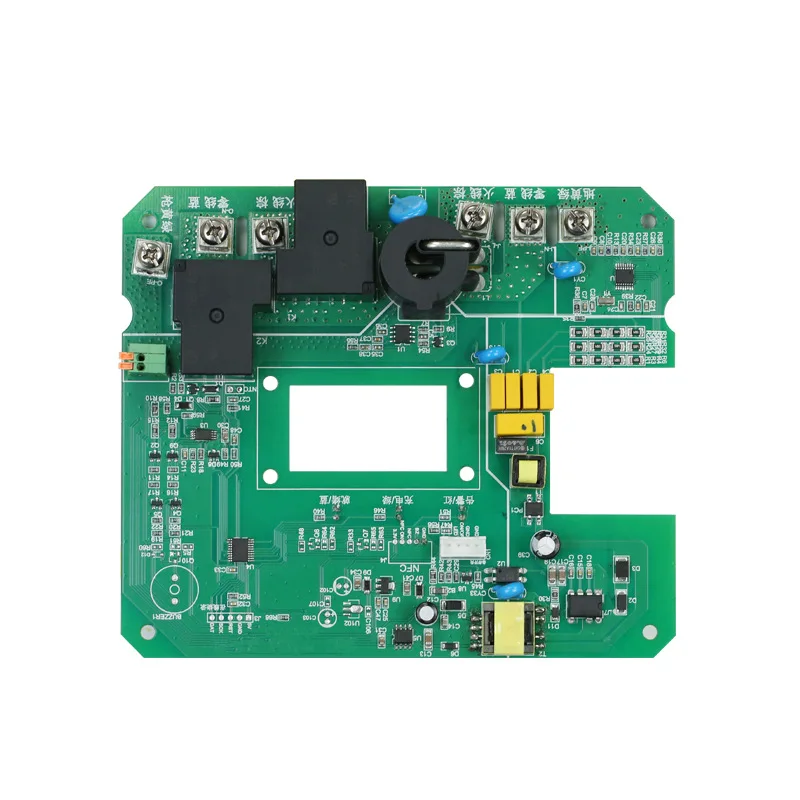

あなたは、自分の電子ガジェットが最初どのように動作するようになったか考えたことがありますか?私たちの技術を機能させるための重要な部品は、プリント回路基板(PCB)と呼ばれます。PCBは、スマートフォンやタブレット、ゲーム機など、日常的な目的で頼りにしている多くの電子デバイスにとって欠かせない部品です。これらは、装置内の異なる部品を互いに接続し、それらを協調して動作させるために使用されます。テクノロジーの世界のほとんどのものと同じく、PCBも進化しており、新しい材料が次々と導入されているため、基板技術は向上に向かっています。

PCB技術における主要な転機の一つは、フレキシブル材料の応用です。従来のPCBは剛性が高く、柔軟ではなかったため、小型デバイスでの使用が困難でした。しかし現在では、エンジニアが曲げたりねじったりできるフレキシブルなPCBを設計することが可能です。この柔軟性は特に小型フォームファクターや移動中に使用されるデバイス(主にスマートウォッチやフィットネストラッカーなど)において非常に有用です。手首の形にぴったりと合うウォッチを身につけることが想像できますか?

3Dプリンティングによる印刷回路基板 - また素晴らしい開発です。3Dプリンティングとは:エンジニアが材料を層状に積み重ねて三次元物体を作り出す方法です。この方法は、PCB設計で必要な高解像度かつ複雑なデザインを作成するために役立ち、多くのお金を節約し、時間を短縮できます。さらに、3Dプリンティングは廃棄物を少なくするため、製造中に捨てられる材料が減少します。これほど早くできるのは素晴らしいですし、環境への負荷も軽減されます!

PCB設計を簡単にする

PCBを開発してテストすることは、エンジニアにとって非常に時間のかかる作業で、イライラすることもあります。しかし、新しいツールやソフトウェアを使えば、これらのプロセスを進める便利さは今までにないものです。

なぜ多くのエンジニアがAltium Designerを使うのか エンジニアやデザイナーが、テスト目的でプリント回路基板(PCB)設計のプロトタイプを作成するために使用するアプリケーションです。Altium Designerの包括的なツールと機能によるリアルタイムインサイト:white-crop: リアルタイムの基板データを利用することで、仕事が正確に進行していることを確認できます。また、同じ場所にいなくてもチームが協力して作業できるコラボレーションツールも備わっています。

助けを借りる:PCB設計をさらに簡単にするには、最良のPCBプロトタイプを使用するサービスを利用してください。これは、エラーや問題なく素早く最初のバージョンの裸の回路基板(プロトタイプPCB)を作成することを指します。PCB設計は最先端技術と手法に基づいており、設計の機能が確実に動作することを確認し、すべての重要な基準を満たします。これにより、エンジニアは製造に関する心配をせずに好きなだけ設計を反復できます。

PCB製造における最新技術

電子機器用の基板を作る工程はゲームの中でも非常に重要な中間ステップであり、これを省くことはできません。新しいアイデアや革新のおかげで、これらのプロセスはこれまでになく速く、簡単かつ安価になっています。

これらの進歩の典型的な例は、新しい組立工程であるサーフェス・マウント・テクノロジー(SMT)です。これは、部品をPCBに穴を通じて配置する方法から、すべての部品を表面に直接配置する完全自動システムへの移行を意味します。このアプローチには多くの利点があり、より小さな電子機器を作ることができ、狭い範囲でより多くの部品を取り扱え、さらに組立工程が高速化されます。これは、現在の技術依存の世界において、製品をより迅速かつ小型で製造できることを示しています。

さらに、ユーザーにとって便利な更新点として、検査システムが大幅に自動化されたことが挙げられます。これらは、PCBに問題がないかを確認し、場合によってはその問題を自動修正機能で修復することができる機械です。これにより、メーカーは早期に不具合を発見し、対処することが可能になり、生産の後段階での問題発生の可能性を減らすことができます。その結果、より信頼性が高く、性能の良い製品が得られるようになります。

IoT用のPCB設計要件セット

IoT(Internet of Things) - IoTは、インターネット接続を使用または介して接続する日常のデバイスを記述するコンセプトです。これは、家電、車、またはウェアラブルデバイスなどがあります。IoTは、これらのガジェットが正しく動作するためにシステムベースの設計だけでなく、非常に複雑なソリューションを必要とするため、PCBデザイナーや製造業者にとって新しい可能性を提供します。

BLEやWiFiなどの統合無線通信技術を備えたPCBが設計されており、これがIoT向けにPCBを構築する方法の一つです。これにより、デバイスは追加の部品に依存しなくなり、さらにシンプルになります。まるで、デバイスの中にミニコンピュータが搭載されていて、それが他のデバイスやウェブと通信できるようにするのです!

消費電力すべてではありませんが、多くのIoTデバイスはバッテリーで動作します。多くのIoTデバイスがバッテリー駆動であるため、PCBデザイナーはデバイスの寿命を延ばし、バッテリーのメンテナンスを少なくするために、低消費電力仕様の部品を使用する必要があります。結局のところ、誰も自分のデバイスを常に充電したいとは思っていません。エネルギー効率の良い部品は、デバイスをより長く動作させ、よりユーザーフレンドリーにするのにも役立ちます。

高性能PCB設計

PCBはスマートフォンから飛行機に搭載されているRFトランシーバーまで、あらゆる場面で使用されています。軍用や医療機器などの高級アプリケーションでは、PCBの使用がさらに厳しく求められます。これらのアプリケーションでは、非常に過酷な環境下でも正常に機能しなければならないためです。

高度な材料を使用することは、これらの増大する要求を満たすための方法の一つです。これは軍用機器においても明らかで、必要なPCBは極端な温度変化に耐えられる選定された材料で作られ、大きな衝撃や振動に耐える必要があります。これにより、過酷な環境下でも信頼性の高い動作が保証されます。一方、医療機器には感染を防ぐためにバイオコンパチブルであり、滅菌可能なPCBが必要です。

信頼性は、高性能PCBにおいても重要な役割を果たします。これらのデバイスが動作を停止すれば、命に関わる状況になる可能性があります。その結果、PCBの設計者や製造業者は、これらの基板が意図した通りに機能することを確保するために、厳密なテストと品質管理プロセスに依存しなければなりません。この細心の注意は、装置が故障せず、必要とされる時間内に最適に機能することを助けます。

全体的に、PCB設計と製造においては常に変化が起こっています。興奮を呼ぶ革新が日々行われており、新しい技術や材料が開発されています。このような進歩のおかげで、私たちの生活だけでなく世界そのものを豊かにする、より魅力的な電子デバイスが期待できます。未来のPCBとはどうなるのでしょうか?…フレキシブルPCB、3DプリンティングされたフレキシブルPCB、またはスマート製造プロセスなど、誰もが予想できません……次世代回路の未来は素晴らしいものになるでしょう!

EN

EN