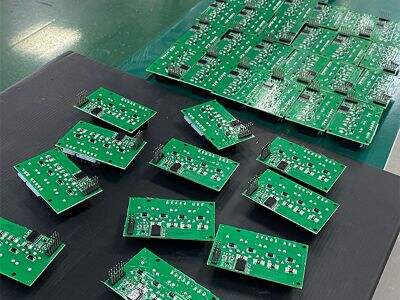

Have you ever wondered how they make the electronic devices you use every day? This type of devices is everywhere such as smartphones, tablets, computers, and an essential part of these devices is something called the Printed Circuit Board (PCB). A PCB (Printed Circuit Board) == PCB is a customized board containing different components and electrical traces for a particular electronic device. It makes all the different pieces of the device work in concert. But a PCB alone is not sufficient. As for building it together, how it is assembled is very crucial to its working. With that being said, today we are going to be looking at how some methods of assembling PCB boards can affect a product's performance and the importance of smart choices when assembling these boards.

The PCB Assembly Factor

However, several factors during PCB design can impact its functionality and performance. There are thermal considerations, power consumption, signal integrity and placement of the various blocks on the PCB. These elements can all have an impact on PCB performance. But along with your choice of how you assemble the PCB itself, called assembly technology, is key. The two most common PCB assembly methods are Through-hole technology and Surface-Mount technology (SMT).

Through-hole technology is a technique in which holes are drilled in the PCB and then various components are inserted into the holes. After the parts are assembled, they are soldered, or connected, together. This is the optimal approach to power large components that need to draw more power. Nonetheless, it is essential to point out that through-hole technology is most poorly designed for smaller parts. It is also more complicated and possibly costly than other methods.

In contrast, Surface-Mount Technology (SMT) is an alternative where no holes are drilled into the PCB at all. Instead, smaller devices are mounted directly on the surface of the PCB and soldered in place. There are multiple advantages of this method. However, it is more reliable and durable because it is better resistant to vibration, shock and temperature variations. Moreover, SMT is relatively more affordable and quicker to manufacture compared to PCB through-hole technology, which is the reason it has become a favored manufacturing method amongst manufacturers.

In Search of Stability and Robustness

Choosing the right PCB assembly method is critical to ensuring electronic devices are reliable and last a long time. You have to consider various environmental factors such as temperature ranges, vibrations, humidity, etc. where the device is going to be used as well when designing a PCB. Finding the appropriate PCB assembly process can mitigate these environmental issues to help the device stand the test of time without functional failures.

The Impact of Your PCB Assembly Decisions on Reliability

The construction of the PCB having a significant impact on its reliability and performance. We said it before, but the right way of assembling it can grapple with rugged environments, temperature variance and moisture. The soldering of components to the board is an integral part of the PCB assembly process. Soldering is a process of joining two metals, most commonly a component and the PCB itself. This is crucial for the units to function properly.

The choice of solder used to anchor the components to the PCB can therefore have a significant effect on the reliability and longevity of the device. For instance, if the solder is too thin or too thick, it can create a weak connection and the device might lose its function. When solder does not join the entire area of a component, it can cause a component to overheat and be damaged, causing the device not to function properly.

Choosing the Right PCB Assembly Method Is Incredible Important

Selecting the appropriate PCB assembly method is critical to make sure the device functions well and effectively. Low-quality components cause durability and reliability issues and can contribute to device failure, a leading cause of device fail which reduces the lifespan of your device. Assembly method selection is something manufacturers must tread cautiously on to ensure that the assembly method is capable of operating in the harsh environments in which the end use product will be operating. Implementing the appropriate assembly technology not only benefits the manufacturers but also the end-users as well as contributing to the environment.

Ultimate Tips to Ensure Product Reliability by Making Smart PCB Assembly Choices

Manufacturers are required to consider PCB assembly decisions very seriously to confirm that products will be trustworthy. The right assembly method must be chosen after proper research keeping in view the needs of the device, production issues, and environmental conditions it would be facing. Manufacturers should use both first-rate components and solder points, and follow them through with re-insertions in devices when applicable. Such decisions should be strategic to help minimize production costs, but still manufacture high-quality products that consumers can trust. That makes communication between the manufacturer, suppliers and the assembler critical to ensuring that reliable devices are available on the market today.

If you're reading this article, you know how critical selecting the appropriate PCB assembly technique is. So, we choose the right assembly technology for our products very carefully. Surface-mount technology is utilized in our PCB assembly process, so quality components and solder materials are used. We work hard to deliver our customers trusted devices that they can use for years without a hitch. These were a few key points about companies that help in PCB assembly. Have questions, concerns or needs about PCBs, talk to us!

IT

IT