Væntanlegur viðskiptavinur Nice sagði: „Ég hef margar spurningar sem tengjast berum PCB plötum.

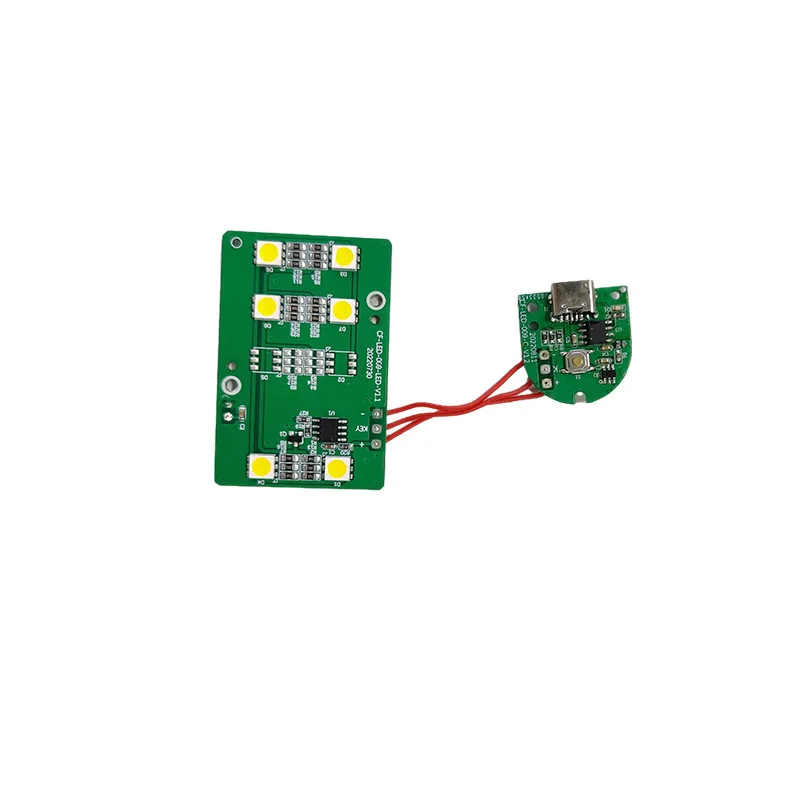

Ber PCB: Nauðsynlegir hlutir fyrir rafeindatæki. Þessar mismunandi meginreglur eru mjög gagnlegar þegar sameina viðnám, þétta, afriðara og smára (meðal annars) sem eru tiltækar í borðinu.

Ef þú vilt, þá eru PCB á byrjunarstigi eins og tómar litatöflur tilbúnar fyrir rafeindaíhluti til að vera felld inn. Þessar plötur samanstanda af óleiðandi efni sem er gert úr einangrunarefninu eins og lagskiptum eða trefjagleri sem síðar er þakið koparlagi og notað til að mynda brautir fyrir rafhleðsluflæði.

Ný framleidd PCB eru ber og eru ekki með rafeindahluti á þeim. Þær mynda frekar grunn fyrir íhlutasetningu síðar meir. Framleiðsla þessara bretta er gerð með því að stafla einangrunarefnisplötu með kopar, ásamt sértækri ætingu í burtu viðkomandi hluta fyrirtækisins til að búa til rafmagnstengi;

Skref 1: Gerð hringrásarborðshönnun Öll hringrásarborðin okkar eru hönnuð með tölvustýrðri hönnun (CAD) hugbúnaði og stillt á nákvæman hátt áður en þau fara í framleiðslu. Þetta mynstur er síðar flutt í filmu og að lokum á koparplötuna. Þessu er svo fylgt eftir með ætingu á umfram kopar til að sýna völundarhús fjölda brauta sem geta verið allt frá mjög einföldum upp í þær sem státa af hundruðum, ef ekki þúsundum eða jafnvel fleiri einstökum þrepum, endurteknum lotum sem öll togibeiðni er háð og lokið á milli mínútna. (mynd 3) í gegnum þar til klukkustundir exec time_$_-completed $loop_OP()$_$1*_one_iteration later/Mynd_4._JSON ~~[**Mynd#5:JSON ***EXEC_END_CYCLE(0)***)].

Eftir að ætingarferlinu er lokið er borðið hreinsað upp og grófar brúnir sléttaðar út - boraðar þannig að hægt sé að setja rafeindahluti í. Að lokum verður PCB húðað með hlífðarskel til að vernda þessar koparleiðir frá því að veðrast með tímanum.

Hvernig á að fá peningana þína frá einni PCB fyrir rafræna hönnun

Það eru margir kostir við að nota ber PCB í rafrænni hönnun. Þessi kjarnasveigjanleiki gerir sérsniðna hönnun kleift að mæta sérstökum þörfum hvers tækis ofan á grunnforskriftir - og þetta hefur komið þeim vel fyrir hjá framleiðendum sem krefjast mikillar sérsniðnar. Þar að auki eru þessar plötur ódýrar og fjöldaframleiddar sem gerir fyrirtækjum kleift að einfalda framleiðsluferlið og draga úr kostnaði.

Ending og áreiðanleiki ber PCB Með því að nýta styrk og seigleika brettaviðar eru þessar plötur nánast ónæmar fyrir umhverfisálagi eins og titringi/hitaáfalli og geta jafnvel þornað út eftir að hafa blotnað sem gerir þær tilvalnar fyrir allt frá farsíma upp í bíla- og geimferðaiðnað. .

Bare PCB: Hagkvæm og aðlögunarhæf lausn á öllum vandamálum þínum með hringrásarborð

Með þessum gagnlegu eiginleikum verða ber PCB aðlaðandi valkostur fyrir fólk sem leitar að sveigjanlegri og hagkvæmri leið fyrir rafrásarþarfir þeirra. Auðvelt er að hanna þau til að passa við breitt notkunarsvið og vegna hagkvæmni þeirra er framleiðsla í miklu magni möguleg.

Að auki er hægt að aðlaga nakin PCB til að mæta þörfum mismunandi tækja, sem gerir kleift að dreifa í margar tegundir tækja. Viðnám þeirra við mjög heitt og rakt ástand gerir þeim kleift að nota í iðnaði.

Að lokum hafa nakin PCB veruleg áhrif til að bæta afköst rafmagns eigur. Þessar töflur leyfa betri virkni rafeindatækja með því að minnka fjarlægð milli íhluta og bjóða upp á meiri hraða með hærri flutningshraða.

Þetta er, eftir allt sem hefur verið sagt og gert varðandi beru PCB-efnin sem þjóna þér algerum grunni þegar kemur að rafeindatækjum sem eru framleidd. Hönnunarsveigjanleiki þeirra, hagkvæmni og traust langtímavirkni veita verulega aðstoð við að viðhalda frammistöðu rekstrareiginleika margvíslegra rafeindatækja og gera sig þannig að óbætanlegum hluta af sívaxandi heimsveldi nútímans: rafeindaframleiðslusviðinu.

eru PCBA hraðafhendingarþjónusta sem endurskilgreinir staðla hraða og skilvirkni. Við höfum fínstillt aðfangakeðjustjórnun auk þess að bæta framleiðsluferli draga verulega úr afhendingartíma lotupantana í aðeins 10 daga. Þetta er stórt prentað hringrásarborð yfir iðnaðarstöðlum. Vegna brýnna krafna kynntum við hraðþjónustuna fyrir litlar lotupantanir með afgreiðslutíma upp á aðeins 72 klukkustundir. Þetta gerir verkefnum þínum kleift að þróast hratt og þú getur nýtt þér tækifærin á markaðnum.

við erum hollur til að útvega berum prentuðu hringrásarborðinu og þjónustu við viðskiptavini til að uppfylla PCBA eins stöðvunarkröfur þínar. FCT prófunarbúnaðurinn hefur verið þróaður í samræmi við prófunarpunkta, skref og forrit viðskiptavinarins. Þetta felur í sér nákvæma uppsetningu, strangar gæðamatsumbúðir og innstungaferli. Hringirnir eru gerðir til að vera í samræmi við alþjóðlega gæðastaðla. Það mun hjálpa til við að tryggja að hlutirnir sem afhentir eru séu af framúrskarandi frammistöðu og langtíma endingu.

Árið 2009 var fyrirtækið stofnað. Hangzhou Hezhan Technology Co., Ltd. státar af aðstöðu sem nær yfir 6,000 fermetra, búin nútímalegum hreinherbergjum sem eru sérstaklega hönnuð fyrir rafeindaframleiðslu. Fyrirtækið sérhæfir sig í rafrænum yfirborðsfestingum og treystir á víðtæka þekkingu sína á iðnaði og býður viðskiptavinum upp á fullkomið PCBA. Um 150 starfsmenn starfa hjá fyrirtækinu, sem samanstendur af framleiðsluteymi með um 100 manns, RD hópur um 50, sölustarfsmenn sem og a. stjórnendahópur. Þar er einnig sérstök OEM deild. Hezhan Technology, með árlega veltu nálægt 50 milljónum júana, hefur orðið vitni að verulegum vexti undanfarin ár á berum prentplötum. samsettur árlegur vöxtur undanfarin þrjú ár er yfir 50%, sem bendir til þess að hann sé í örum stækkunarfasa.

Með PCBA one-stop þjónustunni leggjum við mikla áherslu á mikilvægi „sérsniðinnar þjónustu fyrir hvern viðskiptavin“. Sérhæfð ráðgjafaþjónusta okkar er aðlöguð að hverju prentuðu hringrásarborði. Frá frumhugmyndakönnun til nákvæmrar staðfestingar á tækniforskriftum vinnur sérfræðingateymi okkar náið saman, hlustar á kröfur viðskiptavina og aðlagar á sveigjanlegan hátt ferla fyrir þjónustu og passar nákvæmlega við ýmsar þarfir frá grunni til flókinna með nýsköpun og tækniþekkingu.