So, today we will learn mores on HDI PCB boards. They are actually a type of High-Density Interconnect circuit boards (HDIC) which means they have an exceedingly-high number of connections that densely occupy its space. This unique detail significantly contributes to the slimness and weight of many electronics that we use daily. Moreover, HDI circuit boards are faster and more efficient than standard circuit boards, making them superior in any application.

HDI circuit boards changed the face of electronic design and manufacturing, forever. Electronic devices used to be large so they could fit all of the components needed on their circuit boards. This has been changed by the introduction of HDI press technology, which means devices can be made so much smaller and more ergonomic. This new found versatility opens up a whole new world to designers and manufacturers which will allow them to make much more versatile portables. In addition, using HDI technology makes it easier to modify or improve the circuit board design processors which further supports advancements in technological innovation.

HDI circuit board technology has come quite a long way through the ages: in this post I will discuss various technical breakthroughs and forward steps throughout its evolution. For example, the process of integrating several layers using a single board has given it many boost areas in terms of both performance and energy. Also, the use of laser technology to male tiny holes on the circuit board has helped in setting up more connections within a small space making sure overall size fall short while performance sky-rocket.

The HDI circuit boards play a significant role in facilitating the further miniaturization and convergence of electronic packages, which is absolutely required as portable devices such as cell phones are becoming smaller yet more complex. Take your cell phone as example, its hardware is a system including camera, touchscreen and CPU soMT6572 Smartphoneftware. All these parts need complex interconnections, and HDI circuit boards are the perfect way to achieve this due their small footprint. Put simply, your mobile phone would have to be more physically sizable without HDI technology handling these components-meaning less pocketable and user-friendly.

If you are in the world of electronics design and manufacturing, you may be wondering if HDI circuit boards is right for your business. Whether this type of HDI circuit board technology is useful to you depends on your needs and goals for a project. HDI boards been known to be more expensive and harder to design and make, but they also are a better way of designing smaller electronic devices. The addition of HDI technology means the creation of some much more affordable and compact designs which could not be achieved until now.

To sum up, the application of high performance technology in HDI circuit board embodies some advanced quality transformation information signal and reproduction thinking for electronic products. The HDI technology brings with it tremendous advantages from the point of view of an engineer, designer or end user population alike. We hope this research has helped you gain valuable insights into the realm of HDI circuit boards. Thank you for reading and remember to follow your interest in this exciting subject!!

We are aware of the specific needs of each hdi circuit boards, so, when we offer the single-stop delivery services offered by PCBA we give great importance to the core value of "customized customer service". We offer exclusive one-on-one expert consulting services to ensure every customer can receive tailored solutions. From concept exploration through specific confirmation of specifications for technical requirements Our expert team works closely, listens to the needs of customers, flexible adapts processes for service and is able to accurately match various requirements for projects from simple to complex with innovation and technical strength.

Established in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts manufacturing facility 6000 square meters is equipped with state-of-the-art cleanrooms tailored for electronics manufacturing. Focusing on research and production electronic surface mounting, company based on vast industry experience provide customers with an all-in-one PCBA solution, and is also moving into small-batch manufacturing and online delivery models.There are around 150 employees employed by company. They hdi circuit boards production team around 100 members, an R D department of around 50, sales personnel along with a management staff, and an OEM department that specialized. Hezhan Technology, with an annual turnover close to 50 million Yuan has experienced significant growth in the last few years. The company's compound annual growth rate the last three years is more than 50%, suggesting that it in a rapid expansion phase.

We're a PCBA rapid-delivery solution provider that redefines hdi circuit boards speed. orders that standard we have streamlined manufacturing processes improved supply chain management, reducing the duration of delivery for batches by a whopping 10 days, significantly outpacing industry standards. In recognition of urgent requirements, we pioneered the express service for small-scale orders, with a turnaround time of only 72 hours. ensures your projects are able to move quickly and benefit of opportunities in the market.

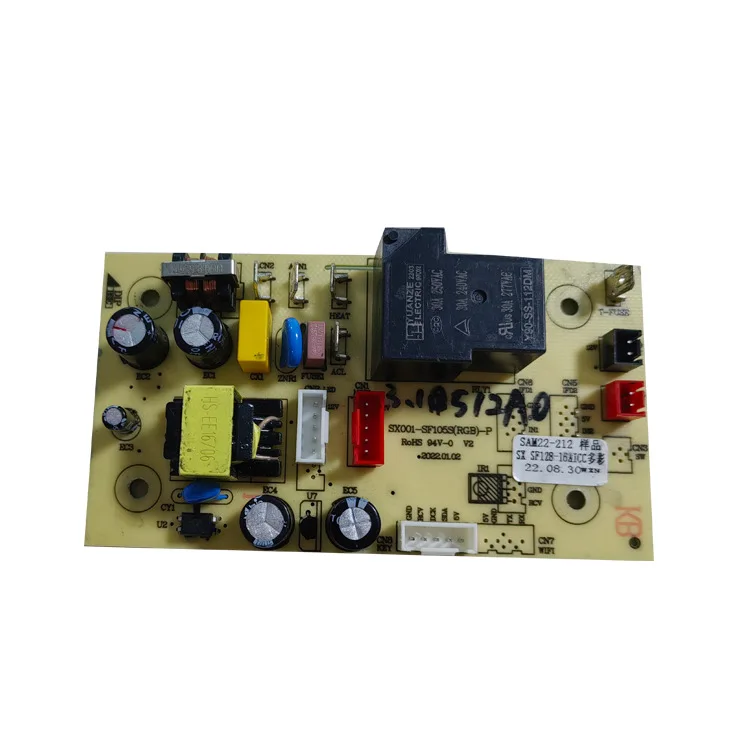

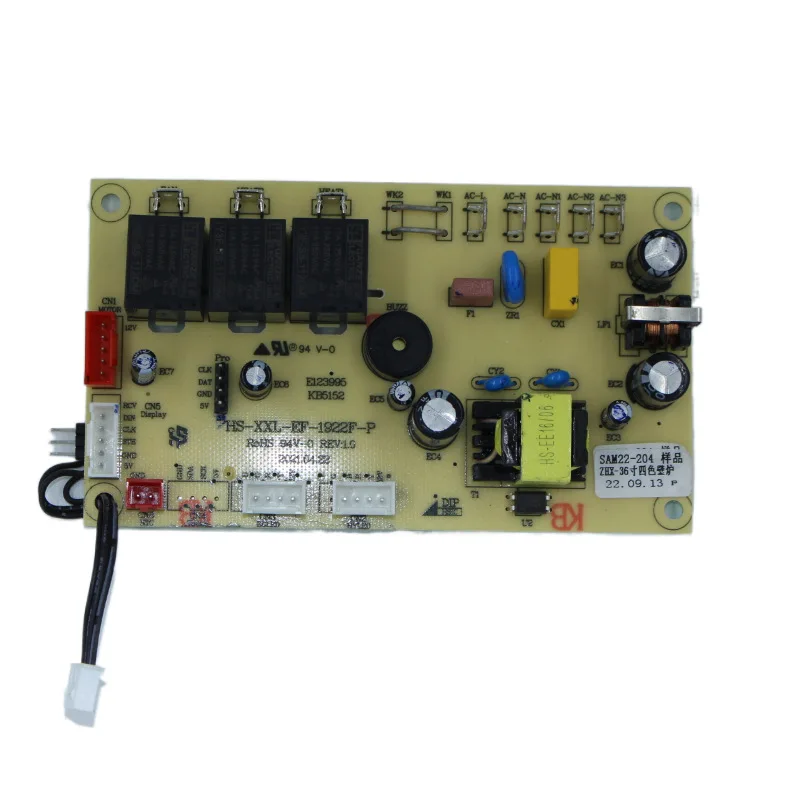

We are specialized in hdi circuit boards a solid consignment quality and service for your PCBA single-stop requirements for delivery. Linked to the highest-quality SMT mounting technology rigorous quality inspection packaging, into the capacity for DIP plugin processing, and PCBA testing because a vital process to ensure the manufacturing and delivery quality. FCT testing fixtures are created and tested according to customer created testing points programs steps. Each ring is rigorously adheres to international quality, that means that those items delivered is of high end and endurance that was long-term.