Als professioneller One-Stop-PCBA-Hersteller sind wir darauf spezialisiert, umfassende PCB-Montage-Prototyping-Dienstleistungen für intelligente Sensoren im Bereich der Internet of Things (IoT) anzubieten. Wir verstehen die hohen Anforderungen an Genauigkeit, Verbindbarkeit und Energieeffizienz von IoT-Geräten, daher konzentrieren sich unsere Dienstleistungen darauf, diese Bedürfnisse zu erfüllen, während wir gleichzeitig schnelle Prototyping-Fähigkeiten und effiziente Serienproduktionsfähigkeiten sicherstellen.

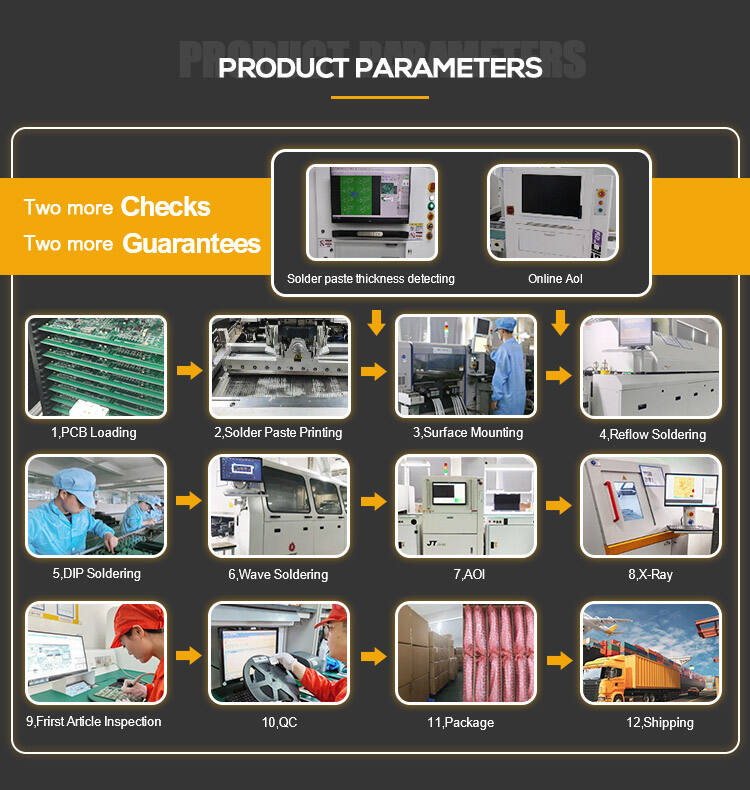

Unser Leiterplattenmontageservice nutzt eine umweltfreundliche grüne Lötzinnsprayschichttechnologie, einen ökologischen Oberflächenbearbeitungsprozess. Diese verbessert nicht nur die Zuverlässigkeit des Lötvorgangs und die Haltbarkeit der Platine, sondern reduziert auch Produktionskosten und den Einfluss auf die Umwelt während des Prozesses. Die grüne Lötzinnsprayschichttechnologie bietet der Leiterplatte eine gleichmäßige und glatte Schutzschicht, die die Widerstandsfähigkeit gegen Feuchtigkeit und Oxidation erhöht und sicherstellt, dass der intelligente Sensor unter verschiedenen Umgebungsbedingungen optimale Leistung aufrechterhält.

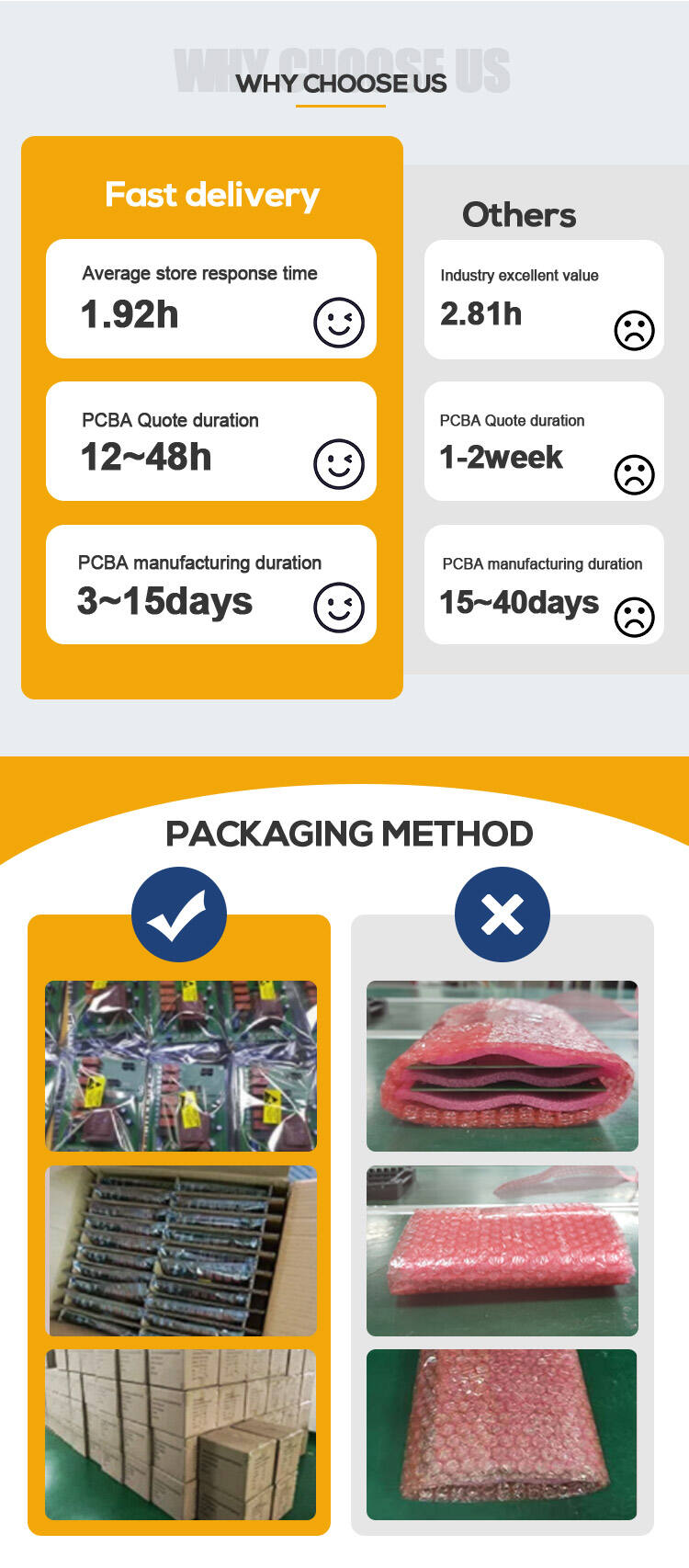

Darüber hinaus können unsere Prototypendienste schnell auf Marktänderungen und Kundenanforderungen reagieren und die Zeit von Konzept bis zum Markt verkürzen. Unabhängig davon, ob es sich um Kleinserientests oder um große Produktionsbedarfe handelt, können wir den Erwartungen unserer Kunden gerecht werden und wettbewerbsfähige Angebote bereitstellen.

Lösungen.

Kurz gesagt, bietet unser professioneller One-Stop-PCBA-Fertigungsdienst eine Kombination aus grüner Lötmaskenspray-Oberflächentechnologie und starker OEM-Unterstützung, um eine effiziente, zuverlässige und umweltfreundliche Fertigungslösung für den Plan von IoT-Smart-Sensoren bereitzustellen. Wir sind daraufhinzielt, unsere Kunden durch kontinuierliche technologische Innovationen und exzellenten Kundenservice beim Erfolg im IoT-Bereich zu unterstützen.

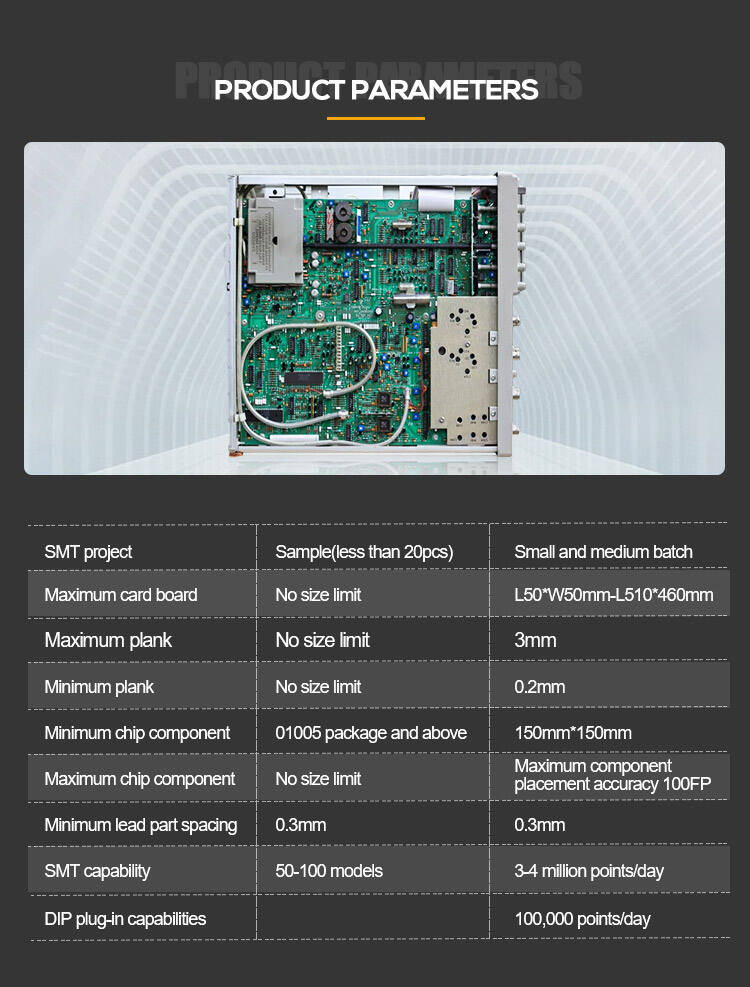

SMT-Projekt |

Probe (weniger als 20 Stück) |

Kleine und mittlere Chargen |

||||

Maximale Kartongröße |

Keine Größenbeschränkung |

L50*W50mm-L510*460mm |

||||

maximales Brett |

Keine Größenbeschränkung |

3 mm |

||||

minimales Brett |

Keine Größenbeschränkung |

0,2 mm |

||||

Mindestbauelement |

01005 Verpackung und größer |

150mm*150mm |

||||

Maximalbauelement |

Keine Größenbeschränkung |

Maximale Komponentenplatziergenauigkeit 100FP |

||||

Mindestabstand von Leiterplattenbestückungsteilen |

0,3 mm |

0,3 mm |

||||

SMT-Fähigkeit |

50-100 Modelle |

3-4 Millionen Punkte/Tag |

||||

DIP-Einbaufähigkeiten |

100.000 Punkte/Tag |

|||||

Unser freundliches Team freut sich auf Ihre Kontaktaufnahme!