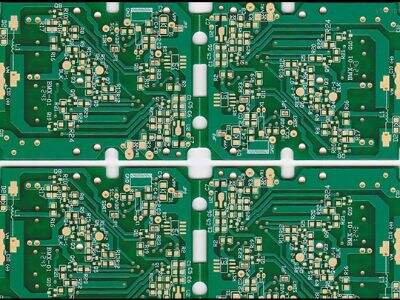

Would you enjoy knowing how the electronic gadgets we use work from our mobile phones to computer? The key part of such gadgets is Printed Circuit Boards abbreviated as pcb. A pcb board is generally speaking a flat board, made out of special materials, with tiny pathways for electricity to follow which connect different parts of the device so they can communicate and work together. Did you know that notwithstanding that, the finish which is used on a pcb, also the outer layer, is generally so important for the overall performance? This discussion is all about understanding proper PCB finish selection significance and its role in improving the performance of electronic devices.

Here are 5 reasons to select the right surface finish on your PCBsDurability: A finish on a PCB protects the disc from PCB failure. A good finish helps the board poorly be affected by humidity, water, and heat. These environmental elements can soon cause problems in the long run. A strong and an enduring finish guarantees that the electrical pathways are smooth and corrosion-proof, keeping safe and hence maintaining the efficiency of the devices.

Aperture: The solderability that would offer a good solder finish is important in soldering electronic components into the circuits within the PCB. This operation is what we call soldering whereby we melt a certain type of metal on the PCB for the solder to cool and form very good connections holding the parts into the whole. The finish smoothens up the surface, allowing the solder to hold up very well onto the board so that these connections do not fall apart easily. Had the connections had been perfect and if so, then the working of the device would have no hindrance.

Electrical Performance: The finishing of a pcb can have a highly significant impact on how the board interacts with electricity. A bad finish-makes it difficult for the electricity to flow through the surface. This can lead to problems like weak signals or slow transmission of information. Good finishes facilitate easy passage of electricity through the device, thus increasing efficiency and reducing electrical hazards.

Cost: The right finish can also make a PCB cost-efficient. Some of these are relatively expensive, giving a better performance and probably even lasting longer. Others can be a more economical choice, but in reality are less durable. It is all about finding that cost-to-quality ratio when choosing a finish, which saves you a lot of cost when you practically check its status.

Corporate Corporate · Compatibility: A finish that will work well with one electronic part may not be for another. The appropriate finish selection assists to ensure that all parts in the device can perfectly work together. If the finishing is proper for those components, then there will be lower chances of a failure occurring or a malfunction taking place. This further enhances the user experience through keeping to intended functionality of the electronic device.

Effects of PCB Surface Finish on Electronics Performance, the Finish, on PCB could significantly influence the electronic performance of the devices. Good PB finishes greatly enhance signals so that they would stay sound and clear even when data are transferred at very high speed. If the end is improperly finished, signal losses, signal reflection, distortion, etc., will be among the possible problems. Understand more on Upwork; however, all of these issues tend to slow down data transfer speeds along the way, and certainly compromise building device functionality.

Hav Finish is also a very essential factor through which heat, which was generated within the board, should escape. A bad finish can shut the heat within and create what is called a hot board. Indeed, all this heat might put the device under stress and finally burn the electronics inside. For example, some devices can be hollow wooden boxes; they require good finishing through which heat can escape effectively such that the device can continue to work better while still functional. This is the reason surface finishing should be chosen wisely to develop the durability and reliability of electronic products.

Just keep the above points in mind while designing pcba circuit board, as it highly influences any PCB manufacturing cost. Not just supplying costs, but even highly efficient PCB finishes will not reflect on how well devices perform; rather, it is about how the device is manufactured. A good finish helps the PCB manufacturing process of fabricating run smoothly and prevents mistakes. For example, using high quality finish enables producing accurate masking during manufacturing. This precision is important as it avoids things like solder bridging, i.e., when solder joins two things it shouldn’t, and shorts, which lead the device to stop working.

EN

EN