In today's era of rapid technological development, smart electronic wearable watch devices have become a popular product on the market, providing users with convenient life experience and health monitoring functions. Hezhan Technology Co., Ltd. meets customer demand for high-quality smart watches by using advanced surface finishing technology to provide PCB board (PCBA) printed circuit boards with superior performance and reliability.

Customized design and functional integration:

The PCBA design of smart watches needs to take into account the miniaturization, low power consumption and high performance of the device. OEM manufacturers will customize the design of circuit boards based on customer needs, including selecting appropriate microcontrollers, memories, wireless communication modules and sensors. During the design process, multi-layer PCB technology is used to optimize circuit layout and signal paths to achieve compact design and efficient performance.

Smart watches usually integrate a variety of sensors, such as heart rate monitoring, step counting, sleep tracking, etc., as well as advanced functions such as NFC payment, GPS positioning and voice assistant to provide users with a comprehensive smart experience.

Applications of surface finishing technology:

Surface finishing technologies, such as HASL, ENIG (electroplated nickel gold), etc., provide PCB boards with excellent welding performance and oxidation resistance, ensuring the long-term reliability and stability of the product. These surface treatment processes not only improve the corrosion resistance of the PCB board, but also enhance the mechanical strength and electrical performance of the solder joints, thus improving the durability of the overall product.

Selection and integration of high-performance electronic components:

The PCBA design of the smart watch uses high-performance microprocessors, memory and wireless communication modules to ensure fast data processing capabilities and stable wireless connections. The selected electronic components comply with industrial standards, ensuring high performance and long-term reliability of the product.

Precision manufacturing and quality control:

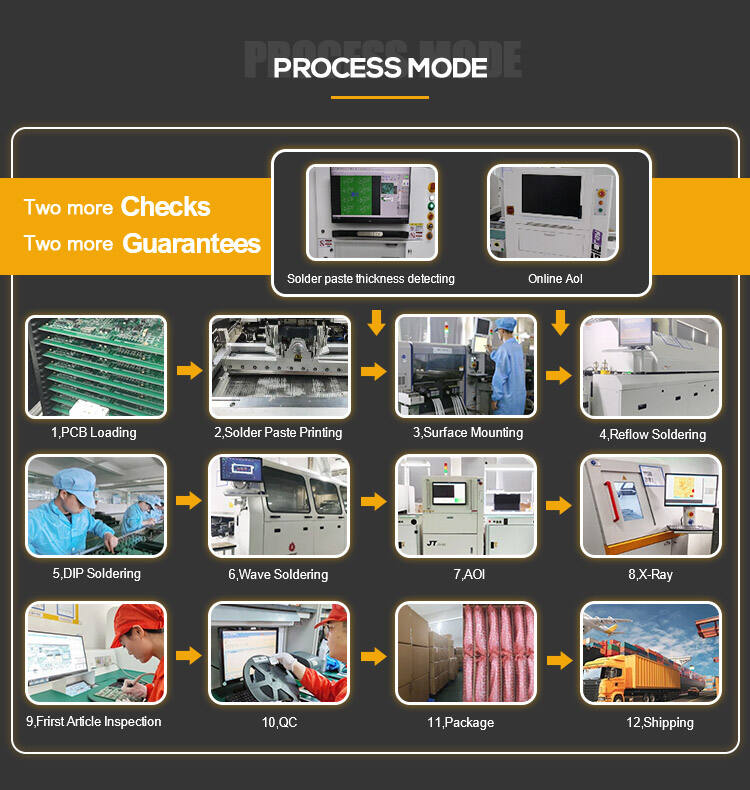

OEM manufacturers use automated SMT production lines and precise assembly technology to achieve high-precision and efficient PCBA assembly. Through strict quality control processes, including AOI testing, functional testing and environmental testing, we ensure that each PCBA meets the highest quality standards.

Low power design and power management:

In response to the special needs of wearable devices, Hezhan Technology Co., Ltd. will adopt low-power design technology and efficient power management solutions to extend battery life and reduce charging frequency. Through intelligent power management chips and software optimization, the watch can achieve longer use time while maintaining high performance.

Environmentally friendly materials and sustainable development:

Hezhan Technology Co., Ltd. is committed to using environmentally friendly materials and production processes that comply with RoHS and other environmental standards, reduce the use of harmful substances, and promote sustainable development. By optimizing design and improving material recycling, OEM manufacturers have promoted the green process of smart watch manufacturing.

Comprehensive technical support and services:

Hezhan Technology Co., Ltd. provides full technical support from concept design to product delivery, including prototype production, small batch trial production, large-scale production and after-sales support. This comprehensive service ensures customers receive expert guidance and support throughout the entire product development cycle.

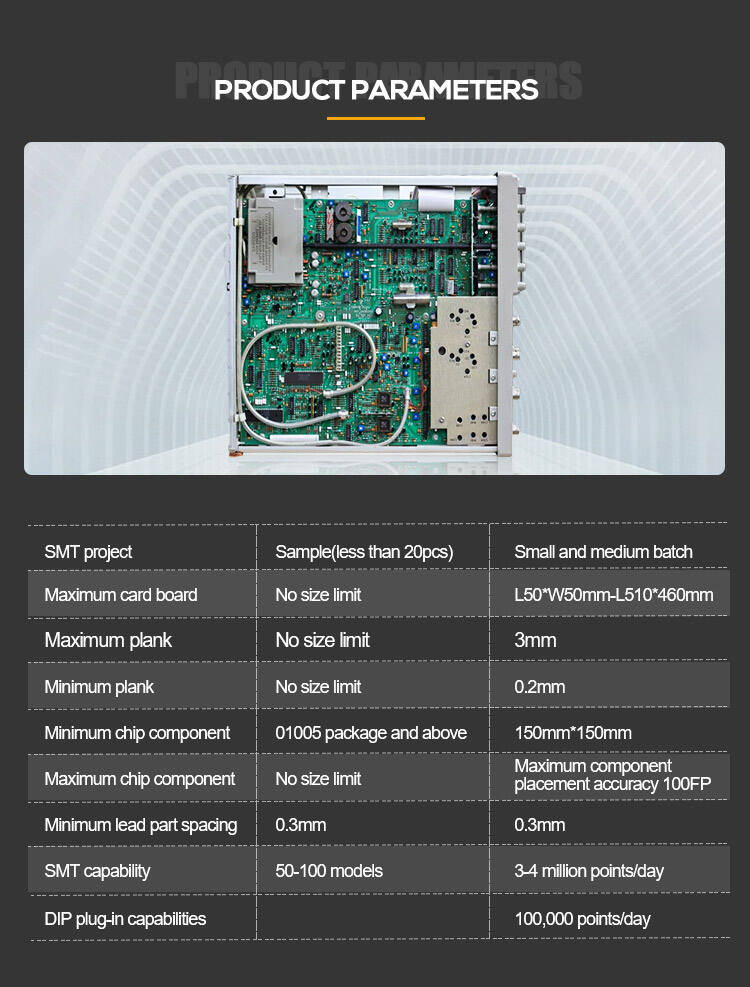

SMT project |

Sample(less than 20pcs) |

Small and medium batch |

||||

Maximum card board |

No size limit |

L50*W50mm-L510*460mm |

||||

maximum plank |

No size limit |

3mm |

||||

minimum plank |

No size limit |

0.2mm |

||||

Minimum chip component |

01005 package and above |

150mm*150mm |

||||

Maximum chip component |

No size limit |

Maximum component placement accuracy 100FP |

||||

Minimum lead part spacing |

0.3mm |

0.3mm |

||||

SMT capability |

50-100 models |

3-4 million points/day |

||||

DIP plug-in capabilities |

100,000 points/day |

|||||

Our friendly team would love to hear from you!