What is a PCB Assembly Factory?

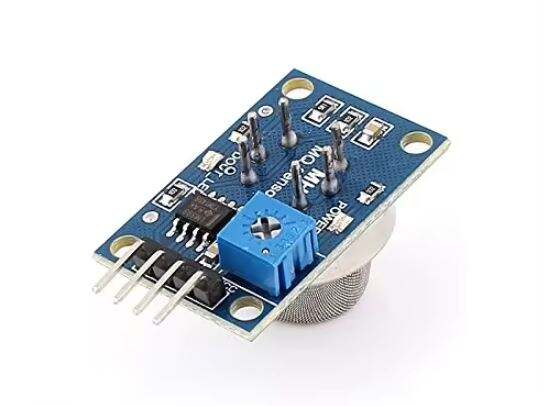

A PCB Assembly Factory means that a designated area in which manufacturing of Printed Circuit Boards (PCBs) takes place by joining them with required electronic components. This process is called the Printed Circuit Board Assembly (PCB Assembly). The PCB Assembly Factory involves in the connection and mounting of the various components on the PCBs in accordance with the design and specifications provided by clients. PCB Assembly Factories are expected to install the PCBs with several circuit structures including the resistor, capacitor, diode, transistor and the ic integrated circuit.

Advantages of Choosing A Top PCB Assembly Factory

As for the principles that are considered to be most relevant for the scope of the electronics manufacturing, quality is on the top of the list. Selecting the right a top PCB Assembly Factory by mailin will make sure that your pcb board get assembled with the best parts and with a lot of professionalism. This will lead to a refined likely product to be safe, efficient, and in a position to meet the necessary requirements of the customers. Further, hiring the professional PCB Assembly Factory will assist you in availing the state of art technology and innovations in the electronics production sector. These changes can drive an increase in productivity, reaction time, and efficiency.

Innovation and Safety

Computing technology used in the electronics industry is improving and hence the manufacturing processes in use by PCB Assembly Factories are also changing. Manufacturers of PCB Assembly are always on the lookout for ways that they can devise new ways that they can improve their efficiency and reduce the cost of production while at the same time enhancing the quality of the product. Security is also of a great concern in the electronics industry especially with the manufacturing of electronics products. Engaging a reliable pcb Assembly Factory helps to meet the intended safety standards of your products during the design and fabrication processes. Manufacturers of these factories have policies of employment that uphold the standard of safety of the products manufactured.

Quality and Turnaround Times

Reliability and time are two essential parameters that may affect virtually any plan related to electronics manufacturing. Leading PCB Assembly Factories make sure to employ the proper techniques and sophisticated tools to ensure that your boards are assembled properly and to your requirements. They also provide flexible turnaround time so that your products are delivered within the shortest time possible. Effective communication – A top PCB Assembly Factory will look at your needs and ensure that you get what you want within the time you expect.

How to Choose The Right PCB Assembly Factory

Actually, selecting the right PCB Assembly Factory is a herculean task that requires an individual to undertake certain activities. Some of the factors that needs to be looked at regarding them involves; their profiles and portfolio, the prices they offer and the time they take to complete the projects. To source raw materials to a factory and get the products manufactured, it is crucial to compare different factories in as many ways as possible just to get the right factory which will suit your budget. It is important to critically evaluate key areas such as factory experience, factory specialty or area of interest, and factory reputation / customer feedback. Moreover, one should consider a factory with long term consistent concern with issues of quality, safety and efficiency in their production.

EN

EN