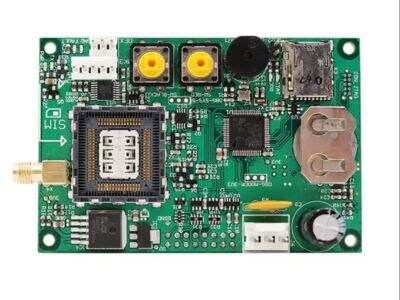

هل سبق لك أن شاهدت شخصًا يلحم؟ تتكون لوحة الدوائر المطبوعة من قطعتين من المعدن يتم توصيلهما معًا، ويبدو ذلك رائعًا. يتم ذلك باستخدام أداة تُعرف باسم لوحة الدوائر المطبوعة بواسطة اللحامين. كانت لوحة الدوائر المطبوعة هذه ضرورية لأنها الشيء الوحيد القادر على تسييل المعدن، ودمجه معًا تمامًا كما ينبغي أن تكون الصواميل والغسالات. كما ترى، هناك العديد من الأنواع المختلفة من لوحات الدوائر المطبوعة، ولكل منها غرضها الخاص الذي تستخدم من أجله. لذا في هذه المدونة، سنطلعك على لوحات الدوائر المطبوعة الشهيرة وكيفية استخدامها في ظروف مختلفة.

مجموعة مختارة من لوحات PCB الشهيرة

هناك ثلاثة أنواع شائعة من لوحات PCB في عالم لوحات PCB — MIG وTIG وstick. MIG هو اختصار لـ Metal Inert Gas وTIG تعني Tungsten Inert Gas. تُعرف لوحة PCB ذات القوس المعدني المحمي أيضًا باسم لوحة PCB Stick. نتيجة لذلك، فإن لوحة PCB المثالية هي لوحة PCB ذات القوس المعدني المحمي. PCB مجلس تم تصميم الطبقات المختلفة لاستخدامات فريدة من نوعها (نظرًا لخصائصها الخاصة). من الضروري معرفة الاختلافات بينها، وهذا سيساعدك في اختيار الطبقة المثالية لمشروعك.

فهم لوحات PCB MIG

في حين أن هناك الكثير مما يجب معرفته عن لوحة الدوائر المطبوعة، فإن لحامات MIG غالبًا ما يقوم بها مبتدئون يتعلمون طريقهم إلى المهنة. تعمل من خلال سلك ذوبان يمكن أن يختلط بالمعادن التي تعمل عليها. هذا يجعلها خيارًا ممتازًا للمبتدئين. تأتي لوحات الدوائر المطبوعة MIG في عدة أنواع، مثل مسدس البكرة وغطاء الغاز من نوع الدفع والسحب. غالبًا ما يتم استخدام مسدس البكرة عند التعامل مع مواد حساسة للوحة الدوائر المطبوعة لأن الألومنيوم البسيط يمكن التعامل معه بسهولة بواسطة الجهاز. من ناحية أخرى، يتم استخدام مسدس الدفع والسحب في مواد أكثر سمكًا ثنائي الفينيل متعدد الكلور اللوحة. هذا السلاح أكثر دقة وكفاءة لإنتاج اللحامات القوية والنظيفة.

متى تستخدم لوحات PCB Stick

إذا كنت بحاجة إلى استخدام لوحات PCB بسيطة وسهلة الاستخدام، فمن المحتمل أن تكون لوحات PCB اللاصقة هي ما يمكن العثور عليه في أغلب المهام البسيطة الشاقة. فهي تستخدم قضيبًا (قطبًا كهربائيًا) يسخن عند حرقه ويختلط بالمعدن الذي تستخدمه. ثني ثنائي الفينيل متعدد الكلور مجلس. هذه ممارسة مثالية للمواد السميكة مثل ألواح PCB والفولاذ والحديد الزهر. ألواح PCB Stick رائعة للأعمال الخارجية لأنها لا تحتاج إلى خزان غاز منفصل، ويمكن أن تكون أكثر ملاءمة للاستخدام في مواقع مختلفة.

EN

EN