When was the last time you opened up a computer or smartphone to see what it looks like on the inside? If you have, chances are that those devices contain minute electronic circuits, without which these would not function. The printed circuit board ties all these circuits together.

Picture a printed circuit board as an intricate jigsaw that has to neatly connect all of the electronic components together. Like a road map for how electricity flows down many roads. Common Printed Circuit Board Varieties Though there are plenty of varying information for general printed circuit table, probably the most applied wide-spread board certainly is the universal move presentationEnter your textual content on this site.

Universal Printed Circuit Board: A universal printed circuit board is a versatile type of PCB that suits several types of projects. With a standard layout, the same board can be reused for any number of different projects without requiring they entire thing to be re-designed each time. Accordingly, this helps saves time and cut costs.

Also, universalized PCBs are super easy to buy and in fact available ready-made either (a) all over the place parked on displays or (b) online. Having them so available makes it easy for anyone who might be interested in getting their feet wet with electronics. This accessibility is democratizing electronics and opening the world of circuits to more people, including those who have been historically marginalized.

A universal PCB is one of the few parts that you can add to your electronics projects which have a massive impact on it. First, it helps to reduce errors by using a standard layout instead of forcing you to tediously determine the placement for every piece. This simplified workflow minimizes wasted time and helps minimize mistakes.

Moreover, a common printed circuit board permits you to experience around with hundreds of various components. When you change parts, you can see how each of them is affecting your project. This should allow for accomplishing a wide range of explorations without having to redesign the board from scratch each time.

Universal PCBs are what allow electronic devices to be accessible for anyone and makes possible that you can build whatever gadget pops into your head without having a whole factory commit errors along the way! Being user friendly they are available in most of the stores which have significantly reduced cash barrier for people to work on some electronics while getting idea how things works.

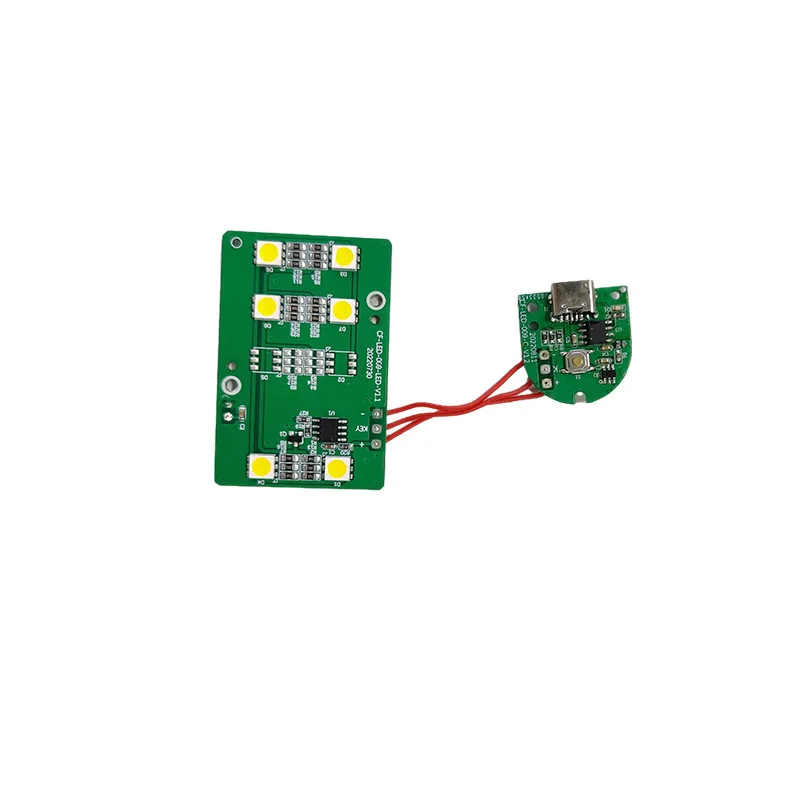

Hangzhou Hezhan Technology Co., Ltd. was founded in 2009 and is home an impressive facility covers 6,000 square meters, complete cleanrooms created to facilitate electronic manufacturing. Focusing the research and production of electronic surface mounting, company based vast industry experience provide its customers with a one-stop PCBA solution, is also venturing into flexible small-batch production as well as online delivery models.company employs approximately 150 employees. This includes production team universal printed circuit board100, an sales, R D and management team of roughly 50 employees, a special OEM division. Hezhan Technology, with an annual turnover of close to 50-million-yuan, experienced significant growth over past few years. The compound annual growth rate over last three years has been more than 50%, suggesting the rapid growth phase.

We are aware of the individual needs of each universal printed circuit board, why, in the one-stop delivery service of PCBA we give great importance to the principle of "customized customer service". We provide exclusive one-on-one professional consultation services to ensure each customer receives individualized solutions. From initial concept exploration to precise confirmation of technical specifications Our expert team works closely together, patiently listens to customer requirements, and flexibly adapts the service process and efficiently matches needs from basic to complicated with creativity and technical rigor.

We're aimed at universal printed circuit board a stronger dedication to our customers to quality and services for your PCBA One-stop delivery needs. The SMT mounting is highly precise and rigorous quality inspection packaging, towards the capabilities of DIP plugin processing, and PCBA testing being a crucial measure to ensure production and delivery quality. FCT testing products is made and tested to generally meet consumer created evaluating points, programs, and steps. Each ring strictly adheres into the product quality requirements and this can be highest in the world, making sure the product try of both exemplary performance and long-term durability.

are a PCBA rapid-delivery service provider that redefines standards speed and efficiency. We have optimized supply chain management well as improved production processes dramatically reduce the delivery time of batch orders to only 10 days. This is a major universal printed circuit board over industry standards. Because of the urgent demands we introduced the express service for small batch orders with a turnaround time of just 72 hours. This allows your projects progress quickly, and you can take advantage of the opportunities on the market.