The Small Printed Circuit Boards, or small PCBs, are so ubiquitously essential to such a vast range of electronic products that we see every day. These small boards are located in most aspects like our smartphones, tablets & desktops. They allow these devices to operate smoothly, enabling us with speed in doing our daily tasks.

Practically speaking, small PCBs allow us to use convenient little electronic tools that help out in our daily lives. These small PCBs find their application basis in a range of devices such as fitness trackers that help to keep track and monitor our health, wireless earbuds which enable us listen music wirelessly without wires and smartwatches keeping all means connected. These devices can be made very small due to the small size of PCBs and we are also carrying it in our pockets/wrist. That way our technology can follow us anywhere!

Computers used to be very large and occupied entire rooms once upon a time. Heavy and unwieldy to carry. Then small Printed Circuit Boards were discovered, and well the rest is history. Computers became faster, made hard drives get way too big for their britches any human ever needed and thus grew into a very serious problem to me. We now have laptops and tablets that we can carry around in our bags, which are super fast to boot. These few square inches of circuit boards have altered the fabric of technology in its entirety while granting us new ways to utilize our gadgets.

Due to its many advantages, Small Printed Circuit Boards are good for electrical tools. Two, they are space-saving in the devices that we use daily. Tiny PCBs to do the job of big hunky parts This, in turn ensures that small PCBs also makes devices very light and portable. They are quicker and easier to produce which reduces manufacturing cost. This in return allows more people to afford these gadgets. The best part about them is that they are not unhealthy for earth and neither cause any waste or energy consumption!

Mini PCBs Are The Set Of the Future In The Technology Industry. They work with companies to build unique, small and light products that pack a lot of power. It has enable inventors and anyone with an idea, to be able design their own products so that it can actually made. This enabled them to make their visions a reality and market it to the masses, thus expanding on technology even further.

are specialist in offering one-stop PCBA quick delivery small printed circuit board, redefining the benchmarks speed efficiency. We have optimized the management our supply chain and simplified production processes reduce batch delivery time to only 10 days. This a significant improvement over industry standards. In addition, meet urgency of our customers, have pioneered express services for small batches, which have a remarkable turnaround of only 72 hours, making sure your projects progress swiftly profits from potential market opportunities.

With the PCBA one-stop service, we place great importance on the importance of "customized services for each client". We offer exclusive one-on-1 professional consulting services that ensure every customer gets a customized solutions. From concept exploration through precise confirmation of technical specifications Our team of experts work closely with each other, attentively listening to small printed circuit board requirements, and flexibly adjusts service processes and efficiently matches requirements for projects from simple to complex using innovation and technical strength.

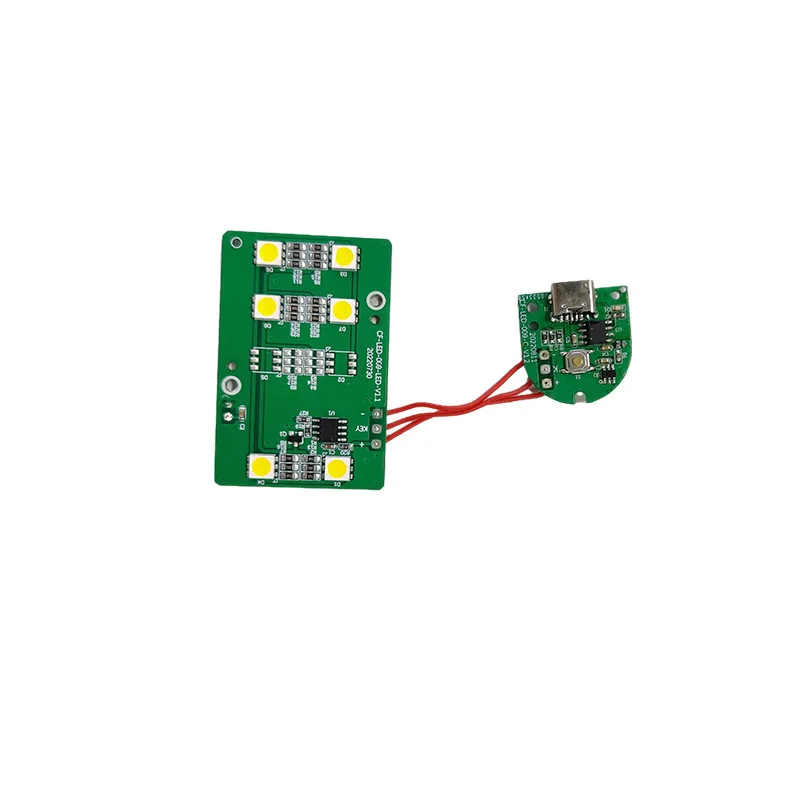

We're aimed at small printed circuit board a stronger dedication to our customers to quality and services for your PCBA One-stop delivery needs. The SMT mounting is highly precise and rigorous quality inspection packaging, towards the capabilities of DIP plugin processing, and PCBA testing being a crucial measure to ensure production and delivery quality. FCT testing products is made and tested to generally meet consumer created evaluating points, programs, and steps. Each ring strictly adheres into the product quality requirements and this can be highest in the world, making sure the product try of both exemplary performance and long-term durability.

Hangzhou Hezhan Technology Co., Ltd. was established 2009 and has an impressive manufacturing facility covering 6,600 square meters of space, equipped cleanrooms specifically madefacilitate electronic manufacturing. The company specializes electronic surface mounting and rely on extensive knowledge the industry in order to offer customers complete PCBA.company employs around 150 people by the company, which includes production team of around 100 people, a R D team of small printed circuit board50, sales personnel with management team, as well as an OEM division that is special. Hezhan Technology, an annual revenue more than 50 million yuan seen significant growth in last couple of years. The compound annual growth rate the last three years is greater than 50%, which indicates that it is in a rapid expansion phase.