What is rigid PCB# Rigid printed board# Hardboard or fixed board This is essentially an insulating layer followed by a conductor pattern part of the product. As the vehicle is constructed from fiberglass and epoxy resin - which are negative material choices in a sustainability context, unless exemplary waste management practices can be guaranteed; this option could only support some low weight components. When printed on to a base of plastic or paper it allows the insulating properties of those materials, but these are just fine lines made from thin copper wireweave running over another (where is tin plated) and thus provides conduits for facing mounted electronic devices.

Some very precise and important are... at the time of design helps to form functional PCB board, with this Rigiding is a process in which rigid pcb can conduct. There are three steps to achieving a supported single-sided PCB layout: Step 1 The base material is first cut into the size and shape, which will be used as the board configuration. Then a thin layer of copper is added delicately to the surface by etching process. These are the Layers that have conductive paths for electricity to pass through this board. Projected blackprint of the design Another application for this mask (mask generated in previous step) is to be used as a "black print" precisely showing where which components need to go on an array using special printers. The design then receives another layer of solder, this material performs the dual function(namely to hold these components in place and connect them together. After each of the components has been placed on the board, they are soldered together to create a sturdy connection that will hold up with continued use.

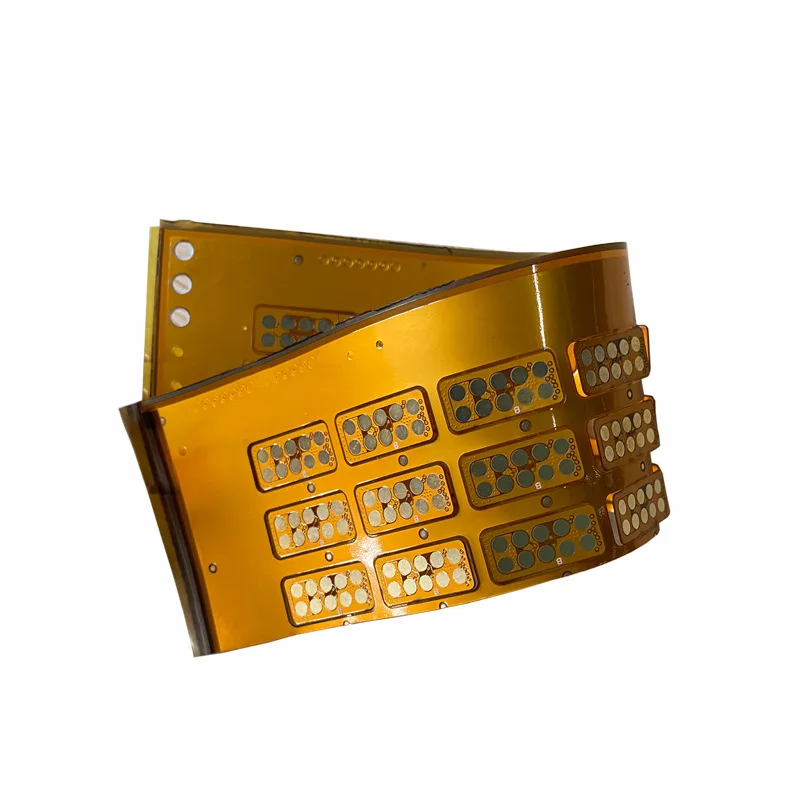

Because of this, rigid PCBs carry a lot advantages in terms of electronics design and are ideal for many applications. Their durability and strength are unparalleled as opposed to other types of boards like flexible PCB boardas delicias Both of these characteristics together insure that the rigid PCB boards are not easily damaged or broke, even from being handled on transported. The two types are employed in high-speed applications but rigid PCB boards provide the best signal integrity, this makes your signals to transmitted more cleanly and effectively end-to-end-thirds of silicone keyboard. Furthermore, they are widely reputed for their affordability and cost duress by design because said simplification makes it cheaper to produce in across the board.

Materials Properties to look for when choosing your Rigid PCB Board Material: Before selecting the material, one should evaluate whether their resist strength and substance properties like mechanical durability and wear resistance over time. This high mechanical strength is in turn used to provide support for the various components, ensuring a long service life. And also to be aware of its electrical properties and what the conductivity, resistance against different atmospheres as well as temperatures. Since this material has very good electrical conductivity, it allows the electronic currents to run without any obstacles under the board which increases its performance. Lastly, analyse the material cost; match up your quality and performance needs versurs its price to discover something that is performant for you among lower grades of steel.

When it comes to high-speed signals and well-needed rigid PCB boards designs are going to be meticulous as possible, simply because whatever you can do just so they would perform best should better be placed in the plan. First of all, you should check whether the PCB board has enough space and straight path to make sure that each high-speed signal is routed correctly. Placing traces and components correctly is also crucial, as doing so will reduce interference and mitigate the chances of signals going astray. Now include your high speed stuff, in locations of minimal impact (as not to introduce more noise or degrade a signal) Choosing Components With Given And Packaged Design Will Enable The Board To Work Amicably In Handling High-Speed Signals. Conclusively, choose low loss dielectric laminate materials and good quality of controlled impedance throughout the board to minimize signal interferences for reliable high-speed signalling.

You can prolong the life and effectiveness of PCB rigid boards by properly maintaining and troubleshooting them during their operational lifecycle. In order to take care of the board for it keep working, You have to ensure a clean and dust-free work location. Do a board level inspection for corrosion, broken traces or components mostly and make the necessary repairs to prevent early death. This why whenever any operational problems hit the board, You should diagnose and remedies all source of interference / signal lost for that particular device to work on never ending mode.

The rigid board (BB for short) is still a more reliable and cheaper one. Conscientious material selection, detail design planning, and carefully considered maintenance practices can contribute to operational performance and the long-term opportunity for rigid boards wherein we will operate.

In 2009, company was founded. Hangzhou Hezhan Technology Co., Ltd. boasts area over 6,000 square meters, which is outfitted with the latest cleanrooms designed specifically to electronics manufacturing. The company specializes in electronic surface mounting relies on its vast industry experience offer clients one-stop PCBA.The company employs approximately 150 staff members, rigid pcb board production team about 100, a sales, R D and management team about 50 individuals, and an OEM division that is specialized. a revenue per year close to 50 million Yuan, Hezhan Technology has experienced substantial growth in recent years, maintaining same rate growth that more than 50% for the last three years, an indication of robust expansion phase.

We are specialized in rigid pcb board a solid consignment quality and service for your PCBA single-stop requirements for delivery. Linked to the highest-quality SMT mounting technology rigorous quality inspection packaging, into the capacity for DIP plugin processing, and PCBA testing because a vital process to ensure the manufacturing and delivery quality. FCT testing fixtures are created and tested according to customer created testing points programs steps. Each ring is rigorously adheres to international quality, that means that those items delivered is of high end and endurance that was long-term.

are a PCBA Rapid-delivery solutions provider which sets standards for rigid pcb board and effectiveness. normal orders have improved the production process optimized supply chain management to reduce the time for delivery of batches to just 10 days. This is far ahead of industry norms. Additionally, in wake pressing demands, we've pioneered express services for small batch orders with a remarkable turnaround of only 72 hours, making sure your projects get off to a flying start and take advantage of opportunities in the market.

We are aware of the individual needs of each rigid pcb board, why, in the one-stop delivery service of PCBA we give great importance to the principle of "customized customer service". We provide exclusive one-on-one professional consultation services to ensure each customer receives individualized solutions. From initial concept exploration to precise confirmation of technical specifications Our expert team works closely together, patiently listens to customer requirements, and flexibly adapts the service process and efficiently matches needs from basic to complicated with creativity and technical rigor.