Printed Circuit Boards, often abbreviated to PCBs are something of an exciting and cool thing that you can do with them just a lot. PCBs are just flat boards that have multiple small electronic parts stuffed with them to make any appliance work. Resistors, capacitors and microchips are among these parts. The most basic PCB will have only one of these electronic components layers but some more complex ones can also consist of many layers on top the other So, in other words: The first step to making a project with an prototype PCB is make the design for it. Now, once you have a design in place, the next step is to construct it. This can be super time consuming and difficult, but the use of rapid prototype PCB assembly has some excellent advantages that make it much clearer.

This entails populating the PCB with all of its parts using a machine that does so more quickly. Software can do it much faster than you could probably type by hand, which will be a lot slower and more error prone. It can also decrease errors when using a machine. They are excellent small parts capable which is an aspect where such machines outperform the handling capacities of people. They save you this cash since with the rapid prototype PCB assembly;Scale production from uber is cheaper than that of short batch slightly massively.

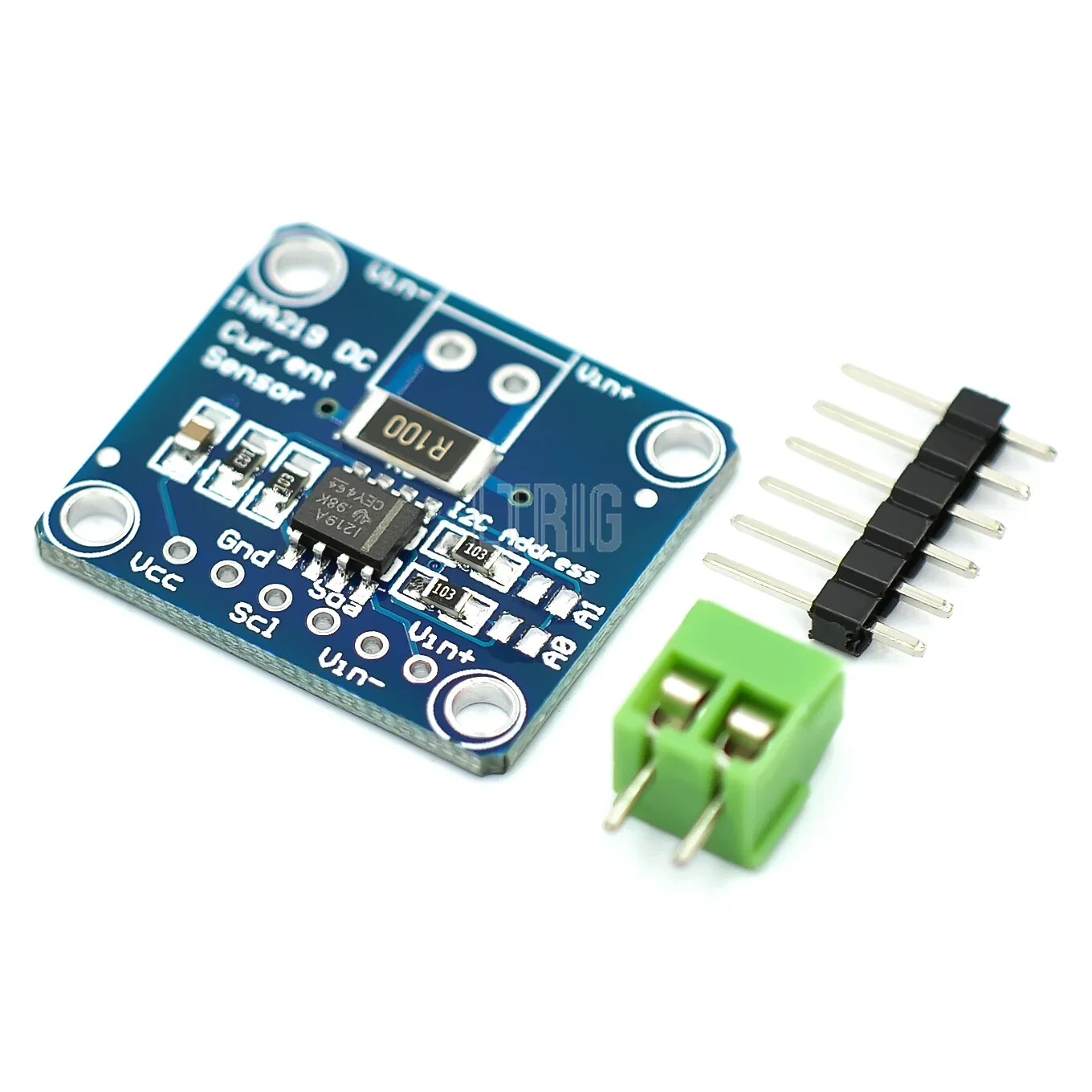

Creating The Design Of Your Prototype PCB:The decisions which are really important to consider at the time of designing prototype pcb. You need to select what components will be used on the board and how each is connected with another. Most people will use a computer program to design their virtual layout before they create the physical board. With this virtual design you can sort out any issues before the build starts and that is an important step. It is very important to be careful the first time you start building your own PCB. You will have to make sure that all items are at the right spot and they should also be connected properly. It will show you got the design right and it is a good habit to check while building, as small issues that can be fixed at an earlier stage become major problems later.

Custom PCBs have many benefits to give them an edge. As they can be of the size that suits particular devices or machines, it makes their work more efficient. A custom PCB can be designed and built to deliver greater integrity than the average store-bought solution. Moreover, PCBs designed per custom specifications can produce electronics that are small and less bulky; thats why soldered boards based on FR-4 board material allowsyou to develop something quite portable. The other nice thing about custom PCBs is that they can be designed to look just so, something very useful if you are creating a consumer-facing item people will use or wear. With the result you can then consider what it looks like and how its going to slot into the changing lives of people that will use flower friction.

There are a few useful tips and tricks if you hand-assemble your PCB. This step must be the boring part but yes, you need to have all your tools in place before doing anything! You will need at a minimum, soldering iron and some small guage wire. A magnifying glass is also useful to see the very small parts more easily. This is why you use your soldering equipment to evenly melt the solder over all of where each part touches them when attaching it onto PCB. Do not use too much solder, as it can cause what is known a short circuit which will affect the operation of your PCB. Last but not least, do test your PCB thoroughly before starting to use it for real applications.

By providing a way to expedite the prototyping process, rapid PCB prototypes are alone making some significant changes in how these boards can and should be designed and constructed. Instead of spending weeks or even months to design and test a prototype you could have faithful working component in just few days. Which means you can write your thinking and begin building quicker than previously. With rapid prototyping you can also change your design quickly if necessary. If you find out that something isn't working like on the paper, change your design and within minutes have an updated PCB printed. The future of PCB layout and design is vast thanks to rapid prototyping, this means there are no limitations on how you can imagine your devices will look like and or do.

In 2009, the company was founded. Hangzhou Hezhan Technology Co., Ltd. boasts facility that covers 6,000 square meters, equipped with modern cleanrooms specifically designed for electronics manufacturing. company specializes in electronic surface mounting and rely on its extensive knowledge of industry offer clients the complete PCBA.About 150 employees are employed by the company, which includes production team with about 100 people, an R D group about 50, sales staff as well as a management team. There also a special OEM division. Hezhan Technology, with an annual turnover close 50 million yuan, has witnessed significant growth over the past prototype printed circuit board assembly years. compound annual growth rate for the past three year is over 50%, which suggests that it is in a rapid expansion phase.

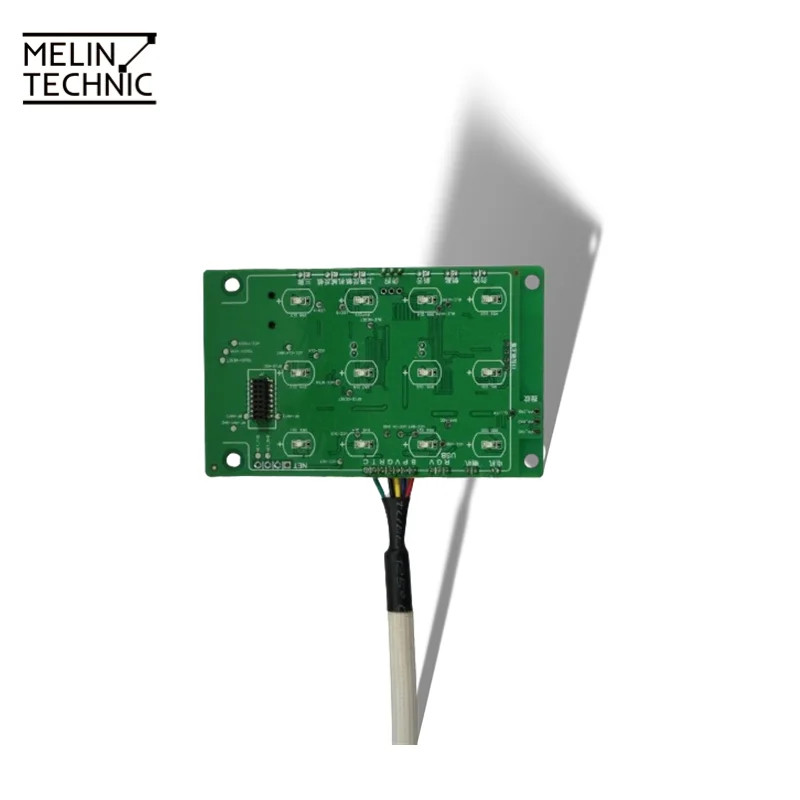

We are going to give you both you and an prototype printed circuit board assembly service commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technologies a strict quality of packaging into the capacity for DIP plugin processing, and finally PCBA testing considering that the crucial approach to make sure that quality of delivery and production, FCT testing fixtures are produced and tested according to customer specified testing points, software and processes. The rings are created to be in accordance with worldwide standards for quality. This helps to ensure that the final product is of superior performance and long-term reliability.

are a PCBA Rapid-delivery solutions provider which sets standards for prototype printed circuit board assembly and effectiveness. normal orders have improved the production process optimized supply chain management to reduce the time for delivery of batches to just 10 days. This is far ahead of industry norms. Additionally, in wake pressing demands, we've pioneered express services for small batch orders with a remarkable turnaround of only 72 hours, making sure your projects get off to a flying start and take advantage of opportunities in the market.

We are aware of the specific requirements of every prototype printed circuit board assembly, so, when we offer the delivery one-stop service for PCBA, we attach great importance to the core value of "customized customer service". Our specialized consulting services are customized to every customer. Our skilled team is able to offer various solutions, from the initial exploratory phase to confirmation of the specifications. They work together to listen to the customer and modify service processes as needed, and match various demands for projects, no matter how either simple or more complex, through innovative thinking and technological power.