You may not be familiar with the word Circuit board, but most likely you have used your smartphone, tablet or even a computer before and played around with other gadgets. The miniscule green particles located within your devices which cause it to work. Circuit boards: These are really important - these basically hold everything in your gadget together and let it talk to itself. But then, even circuit boards undergo plug mold protection. They can be damaged at the mercy of water, dirt or perhaps dust particles. This is why we 'Pot' our equipment. Potting is a coating : we coat the entirety of your circuit board in a special material to protect it from physical damage and provide longer life.

Choose the Correct Matter: There are a number of forms in which potting material could also be determined. Some are so-so by the silicone standard of softness, whereas others solidify as hard or harder than epoxy. You should pick the material that suit with your circuit board to provide a good protection for them.

Clear the Board: Wipe down your circuit board before you begin to pot. If there is water or dirt on the board, they will prevent proper curing and sticking of the potting material A dirt-free surface is crucial in a perfect adhesion.

Much is affected by the potting materials used so be sure to follow manufacturer instructions for each type of material Instructions, read very carefully and follow the steps exactly else you would end up making mistakes.

Wear Safety Gear: When potting your electronics it is a good idea to wear gloves and eye protection. While some of the potting materials can be dangerous to your skin and eyes, it is important that you wear proper protective gear.

Conformal Coating: this is where the circuit board is put in a mold and then potted material poured. After the potting material has dried, you can gently pull your form out. You can produce a hardened defensive sheath nearby the control board through this method.

Method 3: Dipping - In this method you completely submerge the printed circuit board in a potting compound. This is a great choice, especially for small circuit boards as it paints just about every part of the board.

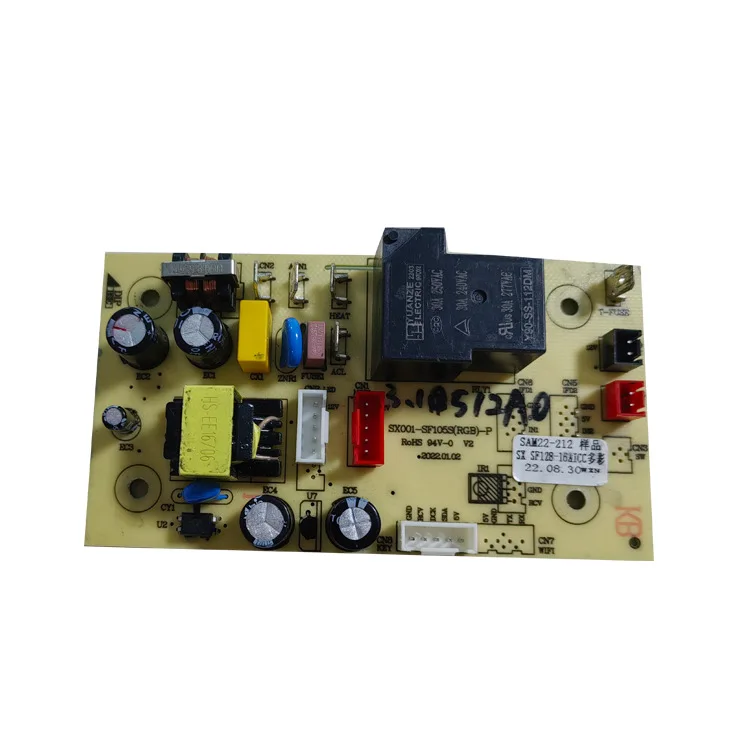

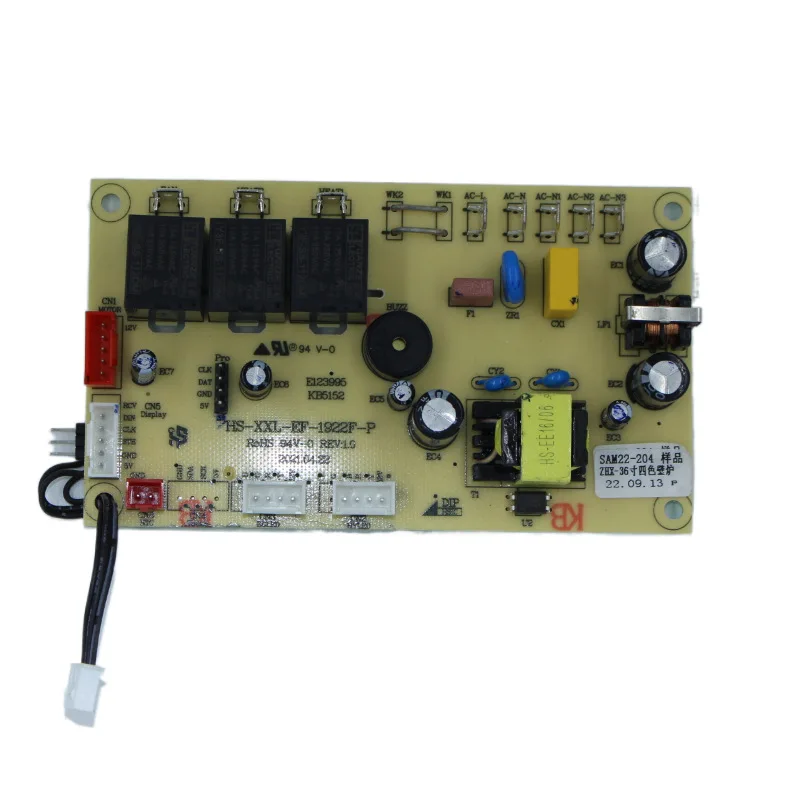

We are going to offer you a potting circuit boards service and a commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technology strict quality packaging to your procedure capabilities of DIP plugin processing, and lastly PCBA testing as a crucial measure to guarantee manufacturing and delivery quality, FCT evaluation fixtures were created and tested to fulfill customer developed testing points, programs and steps. Every ring was created to worldwide quality, which ensures that these products delivered have powerful and long-term endurance.

are a PCBA Rapid-delivery solutions provider that redefines standards speed efficiency. standard orders, we have streamlined production processes and optimized supply chain management, reducing the delivery time of batches by a potting circuit boards10 days, significantly outpacing the industry standard. In recognition of urgent requirements, we developed the express service for small batch orders, which have a turn-around time of only 72 hours. This allows your projects to are able to move quickly and benefit of market opportunities.

We are aware of the individual needs of each potting circuit boards, why, in the one-stop delivery service of PCBA we give great importance to the principle of "customized customer service". We provide exclusive one-on-one professional consultation services to ensure each customer receives individualized solutions. From initial concept exploration to precise confirmation of technical specifications Our expert team works closely together, patiently listens to customer requirements, and flexibly adapts the service process and efficiently matches needs from basic to complicated with creativity and technical rigor.

Founded in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts factory spanning 6000 square meters and is equipped with cutting-edge cleanrooms that are specifically designed to electronics manufacturing. company leader research production electronic surface mounting, company based on its vast industry experience to provide customers with all-in-one PCBA solution, as well as expanding into small-batch production delivery options online.company currently employs around 150 employees, which includes production team approximately 100, a R D, sales, management potting circuit boards of about 50 employees, as well as a specialized OEM division. Hezhan Technology, an annual turnover of close to 50 million yuan, has experienced significant growth last few years. company's annual compound increase over past three years more than 50%, suggesting that it is a rapid expansion phase.