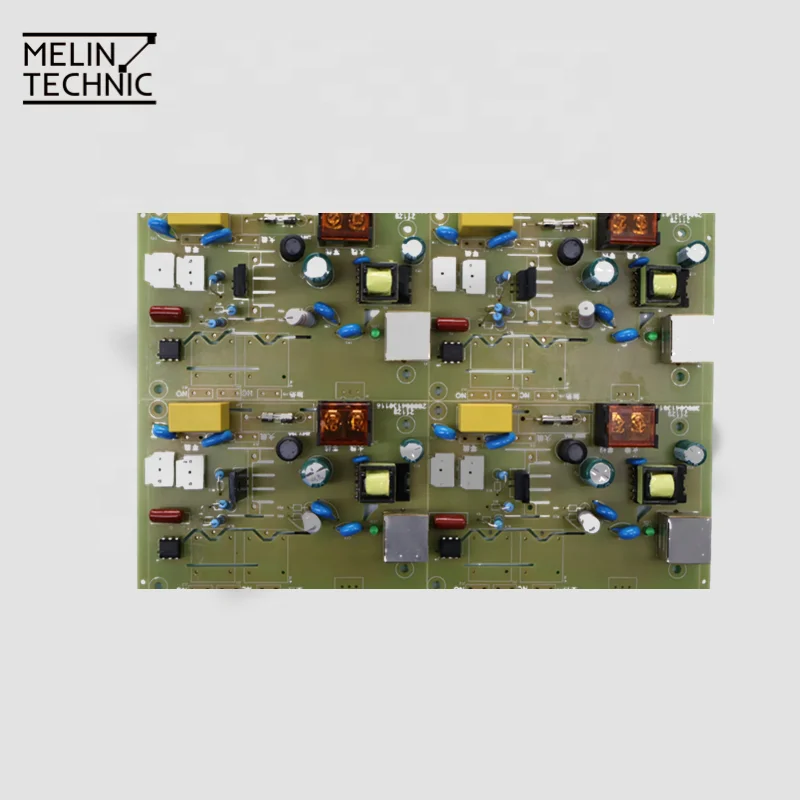

It is a layered circuit board, something like "multi-layered sandwich", where each layer of plastic or glass protects the contacts with very thin copper cladding. We can say that it is made of levels and connected by tiny holes. These are used in things such as Computers and Phones etc.

The substrate is initially a thin material layer for making the multilayer circuit board. The other side gets a layer of copper and is patterned to outline the routing for circuits. This process is repeated for more layers until there are sufficient number of it.

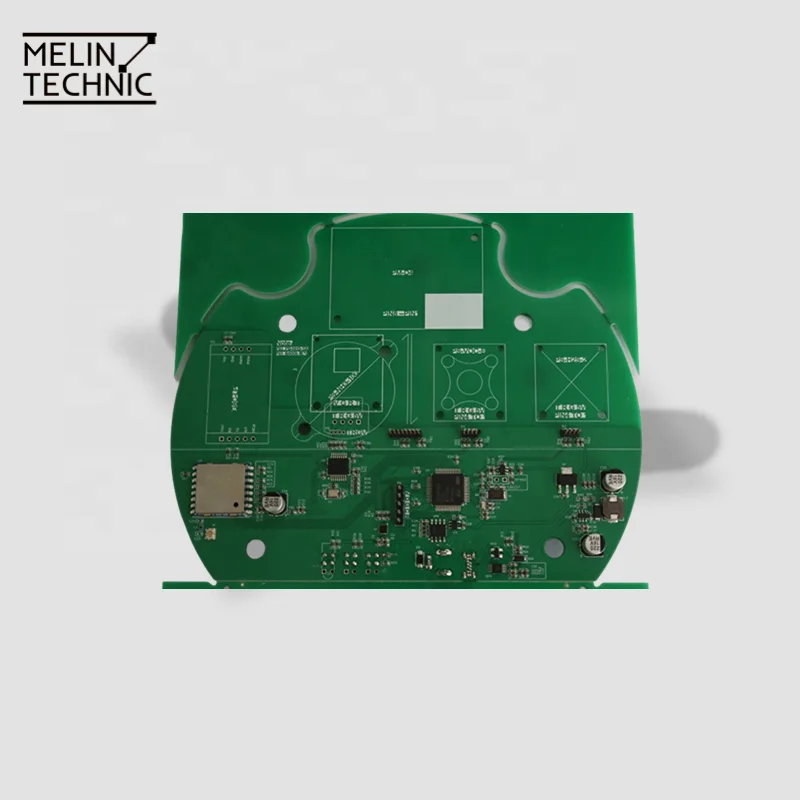

Where these boards become more complex is thinking about how thick each of the layers are, and just as importantly, how large a hole you can drill. Bigger boards are generally stronger, but thicker layers make the board bigger. The smaller the holes, more layer count and fancier circuits are possible but it's very expensive to produce.

On the hardware side, testbeds are being built using new materials (such as graphene) or manufacturing processes. Wise use of multilayer boards enables more complex things that single-layer boards, but they are harder and costlier to repair if something is wrong.

Though multilayer boards do have their share of hurdles, the need for them is paramount in electronics. For companies to continue improving their user stories, they have to keep practicing with new ideas and solutions.

Did you every thought how computers or smartphones on the daily use are working from inside? In this article, we will review the basics of multilayer circuit boards and how these unseen heroes continuously enable our devices to function effortlessly.

Think of a multilayered pcb as an appetizing sandwich, only the layers insides are layered materials stacked each one over the top. These layers perform different functions and are channels between them, creating vias. For instance, this complexity facilitates communication between different electronic components in devices.

are specialist in offering one-stop PCBA quick delivery multilayer circuit board, redefining the benchmarks speed efficiency. We have optimized the management our supply chain and simplified production processes reduce batch delivery time to only 10 days. This a significant improvement over industry standards. In addition, meet urgency of our customers, have pioneered express services for small batches, which have a remarkable turnaround of only 72 hours, making sure your projects progress swiftly profits from potential market opportunities.

Hangzhou Hezhan Technology Co., Ltd. was founded 2009 boasts impressive facility that covers 6000 square meters, which is equipped with cleanrooms designed for electronic manufacturing. The company specializes in electronic surface mounts relies on extensive knowledge of the industry in order to offer customers a one-stop PCBA.Around 150 employees employed by the multilayer circuit board. They include production team of around 100 employees, an R D team of approximately 50, sales personnel with management team, well as a special OEM division. With revenue per year excess 50-million-yuan Hezhan Technology has experienced substantial growth in recent years has maintained compound annual growth rate of more than 50% over the last three years. This evidence of strong expansion phase.

We're specialized in delivering a solid dedication our customers to multilayer circuit board and service for their PCBA one-stop service for delivery requirements. The SMT mounting is highly precise and strict quality packaging, to the process ability of plunge plugin processing, as well as PCBA testing being a vital step to make sure high-quality production and distribution, FCT testing equipment is made plus tested relative to your client designed testing points, programs, and steps. The rings are created to meet international quality. This means that the things delivered are of outstanding reliability plus long-term performance.

We are aware of the specific requirements of every multilayer circuit board, so, when we offer the delivery one-stop service for PCBA, we attach great importance to the core value of "customized customer service". Our specialized consulting services are customized to every customer. Our skilled team is able to offer various solutions, from the initial exploratory phase to confirmation of the specifications. They work together to listen to the customer and modify service processes as needed, and match various demands for projects, no matter how either simple or more complex, through innovative thinking and technological power.