Today we will see an exploration into the fascinating world of a inverter-esqe board! These are the network of devices, which cannot put forth a way in so many areas where we depend upon them In our homes schools and hospitals play an essential role by converting DC power into AC power enabling electricity to reach up.

In addition, like we followed the same Analogy in case of battery inverters that their Job is also converting power from batteries at higher level to lower level as per our requirements So they are basically Power Converters). Think of it in this way, some light bulbs shine bright and reflect very loudly others glow like an ember. This is why inverter circuit boards also control how strong the electric input and output are so that we get them to an optimal level.

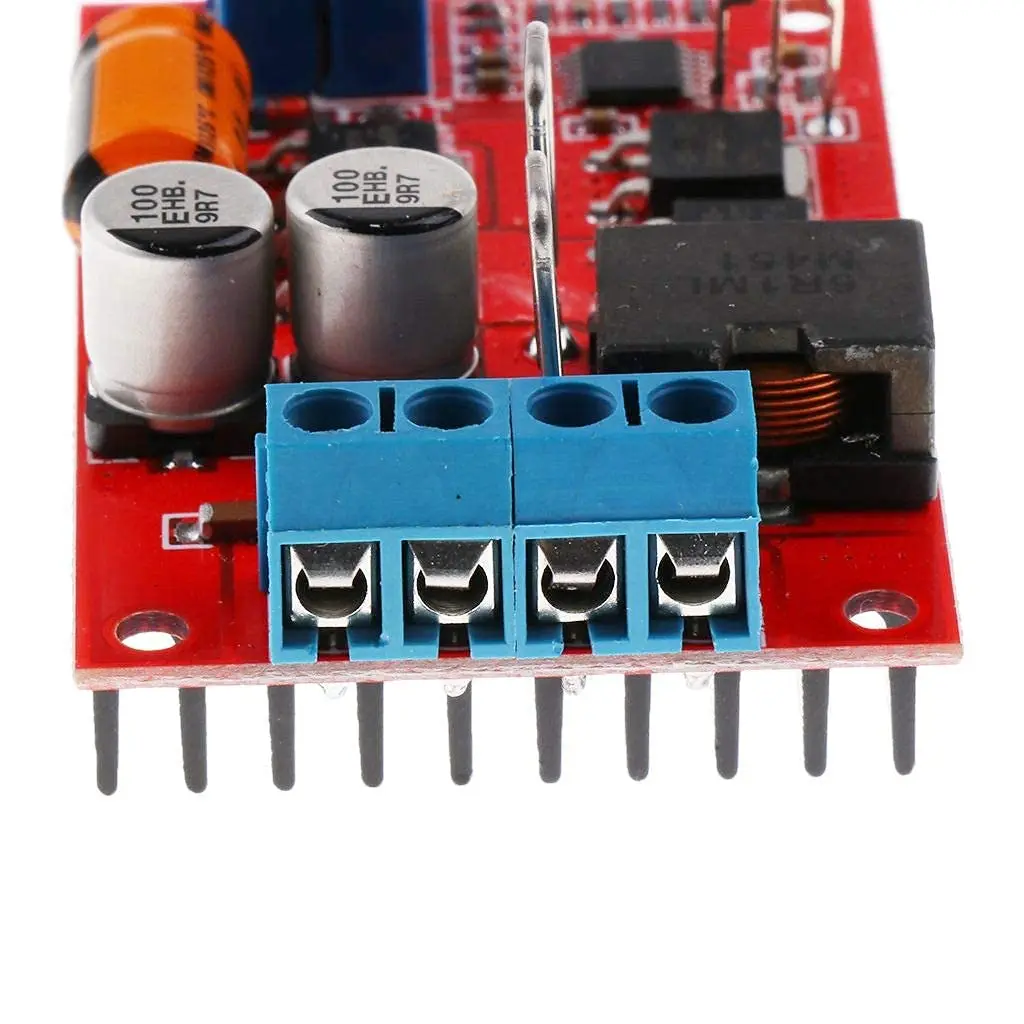

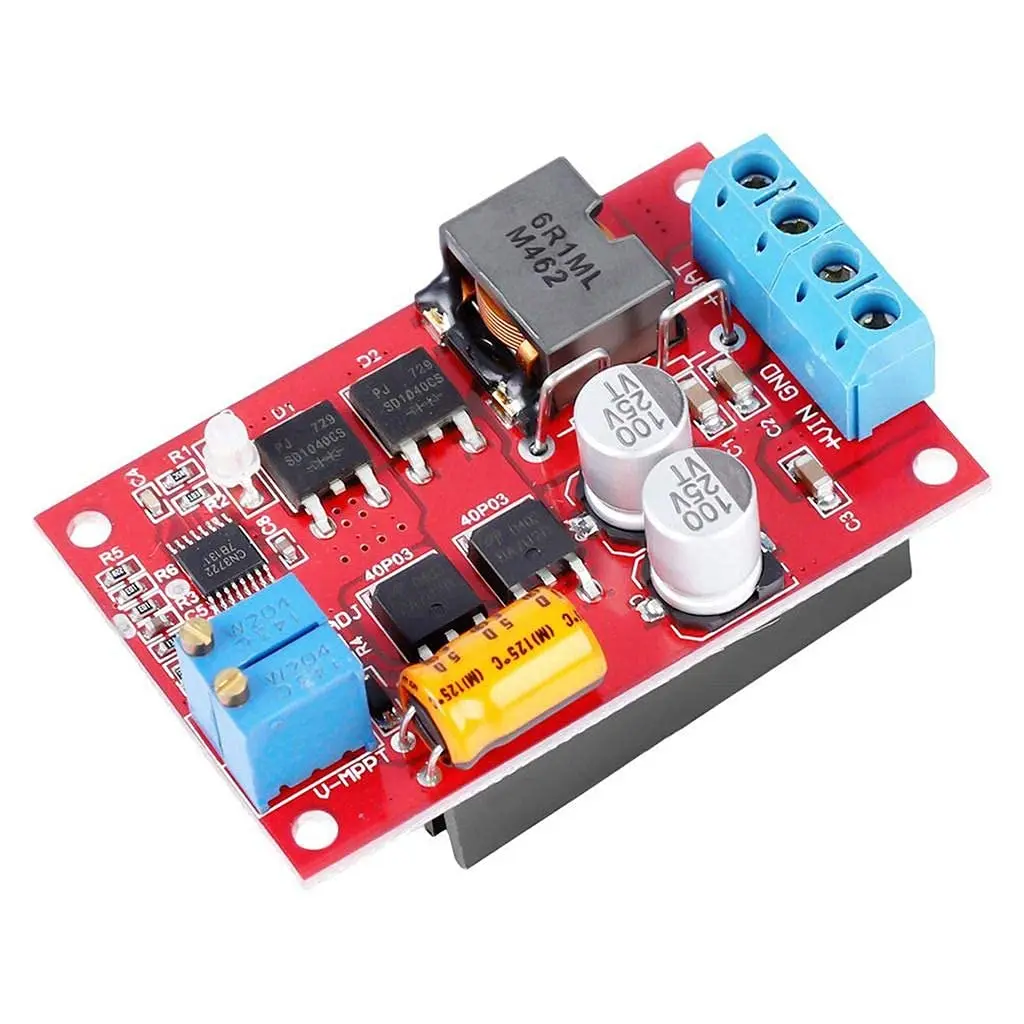

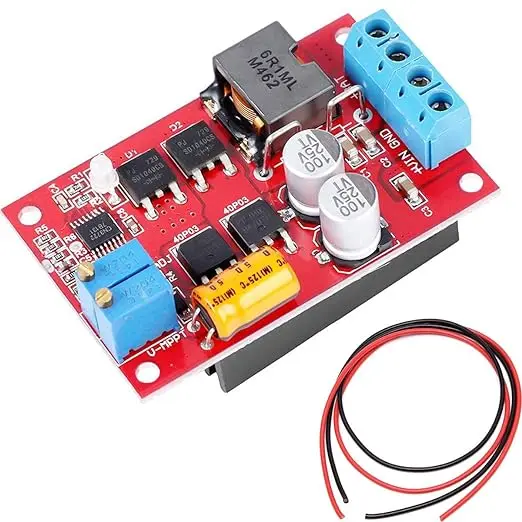

Inverter circuit boards, like all other electronics components use a variety of important parts that combine to make them work as intended. In The above a few regular sections in an Inverter are Microcontrollers, MOSFETs transformers and capacitors. All their individual job is to block the flow power, filter out any instantaneous noise that will be coming from natural energy sources with closed proximity as well and re-route electrical signals whenever needed.

Inverter Circuit Boards | Design and Functionalization

The principle of operation the inverter circuit boards are based on is unique to its design. This would allow for a specific inverter breaker board to be custom-built depending on the different characteristics and capabilities of users. These vary from parameters such as voltage or power, through to things like load ranges. Power Mode: In this mode, when electricity is supplied to the inverter circuit board, Although it enters as DC. With this interface, the microprocessor can regulate not only on/off power data but also variable output level of powers so that its electrical behavior always same irrespective to input voltage and load occurs.

The Ultimate Manual for Soldering Inverter circuit boards with tricks!

Build Your Own Inverter Circuit Boards Trouble No cost As other stuff, the inverter circuit boards will be problems being solved. The troubleshooting of these mishaps will begin by determining the issue that might come up as an outcome from something basic like output power right down to internal hardware failure. To fix these issues one can either use a factory reset or examine the parameters of the board. If Not So Some Parts Needs To Be Scan/Change. It can be daunting to replace a heating element, but by following the manufacturer's instructions or even calling your local appliance repair technicians you should have no trouble at all.

Most research in this space is focus toward improving efficiency, safety functionality etc of (i.e. Inverter circuit boards operate within a live and changing environment especially given the miniaturization technology that grows where we see tiny inverters integrated into small form factor like smart phones, portable speakers or notebooks) Plus solar panels are getting more powerful using high-efficiency photovoltaic cells meaning less overall panels to generate needed amount energy for your home due to changes also with DC volt power being turned into AC power used impedance matching transformation inside an appliance house. Which makes solar power more accessible and affordable to the masses.

How to Examine Inverter Circuit BoardsPhoto sourceFor those that are so keen enough already to start strolling deep into the inverter circuit board rabbit hole, we have it here some invaluable secrets and tips that will guide you on where or how commence.

Please check circuits connection twice time to not short any pin of IC during turn on board.

To avoid the board being affected by debris, or other foreign objects damaging it keep the system clean.

Measure voltages with a multimeter to determine where in the board errors are occurringhouse outlet physics/Q1 part 2 ERROR Conduct at.IC Q1;...

Hazardous materials such as Rocket fuelCircuit boards: Circuit The following items must not be placed in a trash bin.

In short, Inverter PCB seems to be under the control of our lives and emerging in all kinds of puzzle boards as a basic material for electronic products or power us through living space. Some background in circuit board troubleshooting and repair will only end up paying for itself, as well maintaining one's place on the front lines of the battle against electronic waste. Therefore, keep discovering more and be curious to learn new things in life.

we are dedicated to supplying the inverter circuit board and customer service to meet your PCBA single-stop requirements delivery. The FCT testing fixture has been developed in accordance because of the customer's test points, steps, and programs. This includes precise mounting, rigorous quality assessment packaging, and plunge plug-in process. The rings are made to stay line with international standards for quality. It will help to ensure that the things delivered are of outstanding performance and long-term durability.

We're well-aware of the specific requirements of each client, therefore, in our one-stop delivery service for PCBA we give great importance to the core value of "customized customer service". Our specialized consultation services are designed to meet the needs of every client. From preliminary concept exploration to specific confirmation of specifications for technical requirements, our expert team works closely together, listening to the requirements of our inverter circuit board, easily adapts processes for service and precisely matches specifications from simple to complex using innovation and technical power.

We're a PCBA supplier a rapid-delivery system that set new standards speed and effectiveness. have improved our supply chain management as well as streamlining our production processes to reduce batch delivery time to only 10 days. This is a huge inverter circuit board over industry norms. Additionally, wake of pressing demands, we've created express services for small batches, which have a remarkable turnaround time of just 72 hours, which will ensure that the projects run smoothly and take advantage of opportunities in the market.

Hangzhou Hezhan Technology Co., Ltd. inverter circuit board in 2009 has an impressive factory covering 6,000 square meters, complete with cleanrooms that are specifically created to facilitate electronic manufacturing. company specialized in electronic surface mounting and relied on extensive industry knowledge order to offer customers an all-in-one PCBA.The company employs approximately 150 employees. This includes production staff of about 100, a R D, sales, management team roughly 50 employees, and a special OEM division. Hezhan Technology, with an annual revenue over 50 million yuan, witnessed significant growth in the last couple years. The company's average annual growth rate for the last three years more than 50%, suggesting that is in a rapid expansion phase.