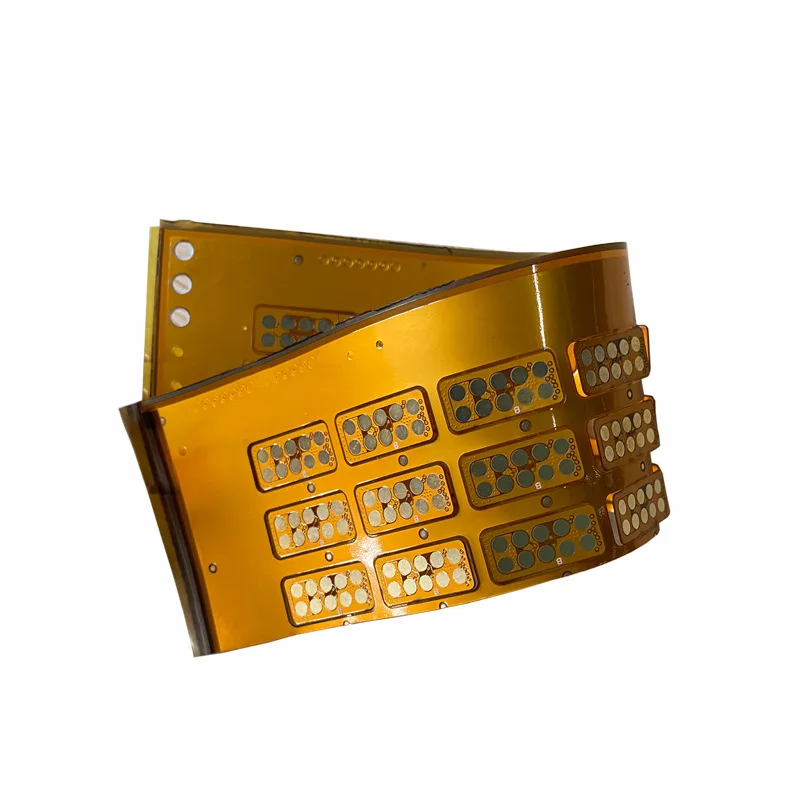

This is a faster, better way to make these PCBs than with the existing slower methods used in manufacturing. So, how does this work? Heating with a magnetic fieldSelectively heat the special material with induction. - Available for all different types of PCBs including multilayer (1, more...). Upon doing so it causes the material to flow electricity in a manner that is necessary for having a circuit board actually operate.

Copper of some type is the best for these kinds of circuit boards, but it can also operate at high-speeds for electronic devices that use cell phones tablets or other wireless gadgets. As they can be made with very thin lines which has a great uniformity, induction PCBs are the most suitable for these fast devices. That allows them to run at the high speeds necessary to move data quickly.

In fast devices, small errors are too much to bear. As an example a minor fault in the circuit board could stop it functioning. Fortunately for you, induction PCBs makes far less mistakes than a regular circuit board. This higher degree of precision ensures the devices are working perfectly when they are used. Moreover, this technology can achieve smaller size and more compact, which is a delicate factor for portable consumer electronics that require lightweight design.

The intelligent units operate ideally with Induction PCBs These come in a huge range of materials that must be able to cope with high temperatures and may have resistance against electrical currents. This resilience allows them to function dependably for an extended period of time without the need for major maintenance or repair efforts. Thus users can have their devices with them without worries that this may fail when most needed.

These problems with heat are effectively solved by Induction PCBs through its engineered approach. They have been constructed out of different materials which not only help to absorb heat quickly but also ensure that the device remains cool preventing them from overheating. This is important as it helps in prolonging the life of electronic devices and prevent them from being sent to a repair service. In short, by managing heat properly Induction PCB keeps devices safe and alive longer.

Whether it is testing new devices or mass producing, induction PCBs have a lot of perks. For testing, induction technology provides a fast and accurate way to make design changes. New versions of a device can be created quickly, and with less errors made throughout the process. These savings translate into real dollars, which is helpful to organizations focused on strategy and growth.

In the case of mass production, induction PCB manufacturing practices are performed so that each device would be made with a high quality and accuracy. This consistency ensures that every device will operate as designed each time it is ever used. Furthermore it shortens the manufacturing time which means more devices could be manufactured and in a higher quantity for less costs. Consumers win with more choice in the types of electronic devices available to them.

Established in 2009, Hangzhou Hezhan Technology Co., Ltd. boasts manufacturing facility 6000 square meters is equipped with state-of-the-art cleanrooms tailored for electronics manufacturing. Focusing on research and production electronic surface mounting, company based on vast industry experience provide customers with an all-in-one PCBA solution, and is also moving into small-batch manufacturing and online delivery models.There are around 150 employees employed by company. They induction pcb board production team around 100 members, an R D department of around 50, sales personnel along with a management staff, and an OEM department that specialized. Hezhan Technology, with an annual turnover close to 50 million Yuan has experienced significant growth in the last few years. The company's compound annual growth rate the last three years is more than 50%, suggesting that it in a rapid expansion phase.

In the PCBA one-stop service, we put a lot of emphasis on the value of "customized services for each client". We offer exclusive, one-on-one professional consultation services to ensure every induction pcb board can receive tailored solutions. Our expert team can provide various solutions, from the initial exploratory phase to confirmation of specifications. They collaborate closely with the customer, adapt service processes flexibly and meet various requirements for projects, basic or intricate, with innovative thinking and technological power.

are specialist in offering one-stop PCBA quick delivery induction pcb board, redefining the benchmarks speed efficiency. We have optimized the management our supply chain and simplified production processes reduce batch delivery time to only 10 days. This a significant improvement over industry standards. In addition, meet urgency of our customers, have pioneered express services for small batches, which have a remarkable turnaround of only 72 hours, making sure your projects progress swiftly profits from potential market opportunities.

We're specialized in delivering a solid dedication our customers to induction pcb board and service for their PCBA one-stop service for delivery requirements. The SMT mounting is highly precise and strict quality packaging, to the process ability of plunge plugin processing, as well as PCBA testing being a vital step to make sure high-quality production and distribution, FCT testing equipment is made plus tested relative to your client designed testing points, programs, and steps. The rings are created to meet international quality. This means that the things delivered are of outstanding reliability plus long-term performance.