Electronics are the lifeblood of our daily lives, it engulfs us in this technological universe. We know how to use these machines because they are constantly used by us in our daily lives, be it a smartphone or one of the kitchen appliances. Wondering how all those gadgets actually work? To know what a resistor is, along with other basic electronic components. If you are into do-it-yourself (DIY) electronics, learning about those components and how they work is a must.

Resistors - Resistors are small, static components that control the flow of electrical current in a circuit. They are precisely built to restrict the current and lower in voltage. There are different kinds of resistors available in the market, like fixed which have a set resistance and variable whose value can be changed.

Capacitors: Components which store electrical energy in an electric field. Voltage regulators are used to prevent damage due from output voltage spikes or unwanted noise, and for storing energy in timing circuits.

Diodes: The semiconductor components that only allow the current to flow in a single direction. They are most commonly used in rectifier circuits that provide a means for converting AC voltage into DC output.

Bye transistors - electronic switches that are keys to amplifying and switching one electric signal over another which is crucial for all kind of computer functions. They are available in two varieties: NPN and PNP.

LED: Light-Emitting Diode; These are diodes that radiate light when a circuit is turned on. LEDs are common in commercial and residential lighting, they the modern light source available today for a variety of applications.

Although electronics might seem complicated, they all are based on basic principles. Well, one of those is Ohm's Law that explains the relationship between current, voltage and resistance. This definition says that, the amount of current which a conductor connecting those two points could carry is directly proportional to difference in voltage between these 2 points and inversely proportional to its impedance (resistance).

A related but important concept are that of circuit elements - resistors, capacitors and inductors which come into play while making an electronic circuits. These properties control the action of these elements, which include resistance, capacitance and inductance.

Electronic circuits are composed of various components which include passive components like resistors, capacitors and inductors as well as active elements such as transistors... integrated circuits. Resistors and capacitors are examples of passive components as they require no energy supply in order for them to work, yet the power from an external system can be used to achieve this. Active components, which rely on a source of energy and not only directional but have the ability to further control signal power are needed as well,. Transistors (bipolar junction -BJTs BJT or FETs) represent this type of controllable activd directionality.

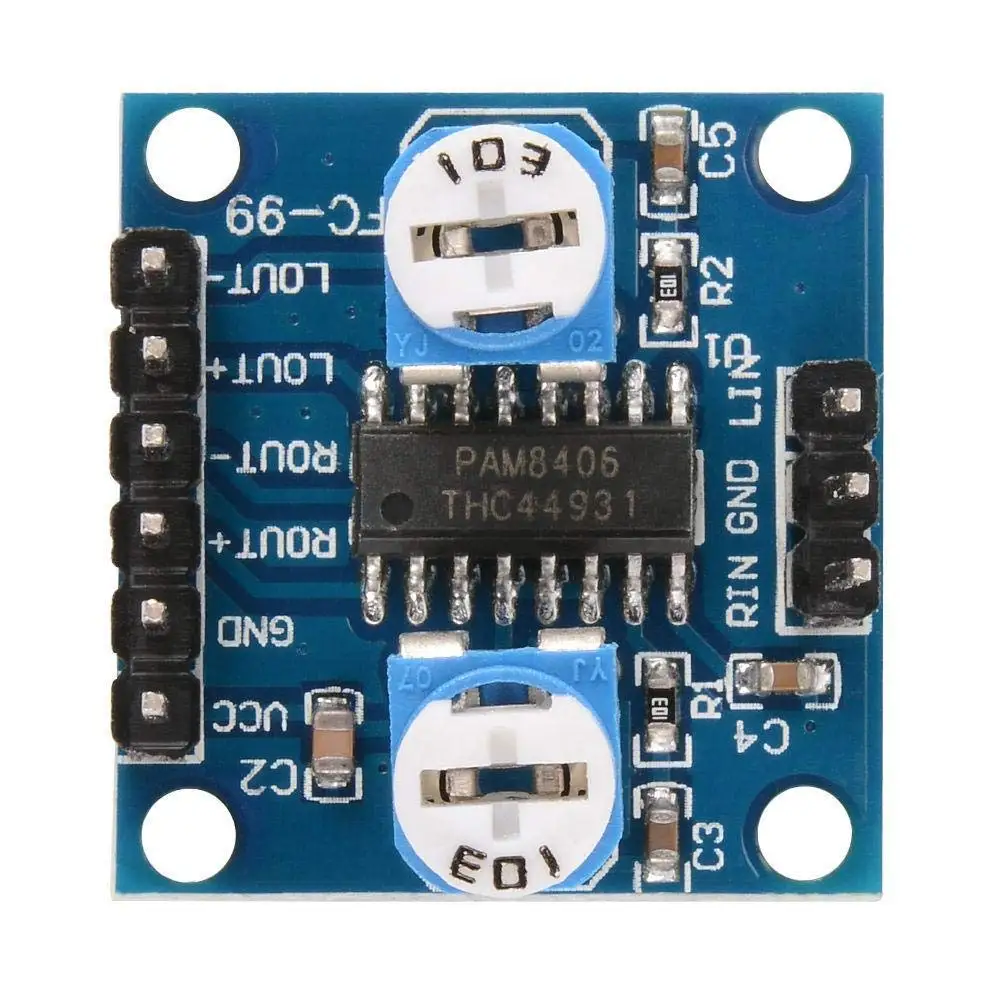

ICs (Integrated circuits - Chips that embed a variety of electronic component) They are a key in the design of complex circuit such as microprocessors, memory chips.

There is enough content out there for people new to the world of electronics. But then that would be like learning from online tutorials / courses to get the basic idea of circutry and components.

Real beginners tips like select the right components for your project, use bread board to simulate Circuits and learn how read circuit diagrams...the usual stuff. It also helps to have a general knowledge of electronics too, including Ohm's Law and components used in circuits.

Given this, we can conclude that they are the first thing many modern electronics circuits have in common. It is the knowledge of how they work and operate that, for those who pursue DIY electronics, cannot be passed by. Anyone willing to learn can start making electronic circuits and devices with a few simple tools.

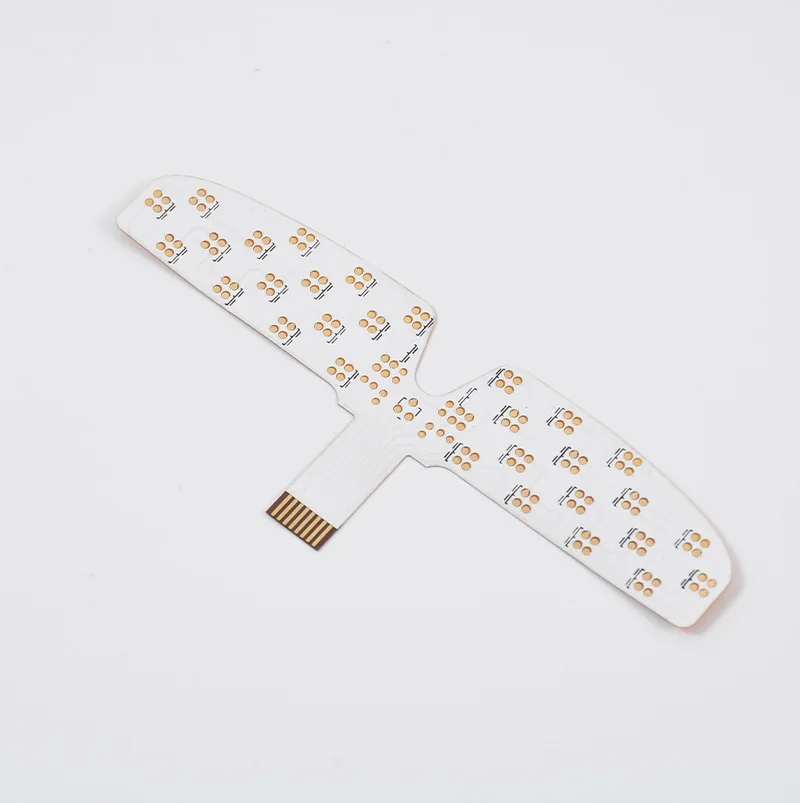

Hangzhou Hezhan Technology Co., Ltd. basic electronic components in 2009 has an impressive factory covering 6,000 square meters, complete with cleanrooms that are specifically created to facilitate electronic manufacturing. company specialized in electronic surface mounting and relied on extensive industry knowledge order to offer customers an all-in-one PCBA.The company employs approximately 150 employees. This includes production staff of about 100, a R D, sales, management team roughly 50 employees, and a special OEM division. Hezhan Technology, with an annual revenue over 50 million yuan, witnessed significant growth in the last couple years. The company's average annual growth rate for the last three years more than 50%, suggesting that is in a rapid expansion phase.

We are going to offer you a basic electronic components service and a commitment to excellence in most your PCBA requirements. With high-precision SMT mounting technology strict quality packaging to your procedure capabilities of DIP plugin processing, and lastly PCBA testing as a crucial measure to guarantee manufacturing and delivery quality, FCT evaluation fixtures were created and tested to fulfill customer developed testing points, programs and steps. Every ring was created to worldwide quality, which ensures that these products delivered have powerful and long-term endurance.

We're aware of the specific requirements of every basic electronic components, so, when we offer the one-stop delivery service of PCBA, we attach great importance to the core value of "customized customer service". We offer exclusive one-on-one expert consulting services that ensure every client receives customized solutions. From concept exploration through specific confirmation of specifications for technical requirements our team of experts works closely together, listening to the needs of customers, flexible adjusts service processes and is able to accurately match various requirements for projects from simple to complex, utilizing innovation and technical expertise.

We're a PCBA rapid-delivery solution provider that redefines basic electronic components speed. orders that standard we have streamlined manufacturing processes improved supply chain management, reducing the duration of delivery for batches by a whopping 10 days, significantly outpacing industry standards. In recognition of urgent requirements, we pioneered the express service for small-scale orders, with a turnaround time of only 72 hours. ensures your projects are able to move quickly and benefit of opportunities in the market.